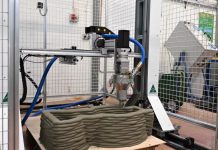

NASA and Aerojet Rocketdyne of West Palm Beach, Fla., have recently finished testing a rocket engine injector made entirely through additive manufacturing – 3-D printing.

Feb. 24, 2011

The space technology, NASA believes, could lead to more efficient manufacturing of rocket engines, saving companies time and money.

‘A series of firings of a liquid oxygen and gaseous hydrogen rocket injector assembly demonstrated the ability to design, manufacture and test a highly critical rocket engine component using selective laser melting manufacturing technology,’ NASA.

NASA’s Glenn Research Center in Cleveland conducted the tests for Aerojet Rocketdyne through a non-reimbursable Space Act Agreement.

‘NASA recognizes that on Earth and potentially in space, additive manufacturing can be game-changing for new mission opportunities, significantly reducing production time and cost by ‘printing’ tools, engine parts or even entire spacecraft,” said Michael Gazarik, NASA’s associate administrator for space technology in Washington. “3-D manufacturing offers opportunities to optimize the fit, form and delivery systems of materials that will enable our space missions while directly benefiting American businesses here on Earth.’

According to NASA, typically this type of injector manufactured with traditional processes would take over a year to make but with 3D Printing it can be produced in less than four months, with a 70 percent reduction in cost.

“Rocket engine components are complex machined pieces that require significant labor and time to produce. The injector is one of the most expensive components of an engine,” said Tyler Hickman, who led the testing at Glenn.

Aerojet Rocketdyne’s additive manufacturing program manager, Jeff Haynes, believes the injector represents a significant development in the application of additive manufacturing.

“The injector is the heart of a rocket engine and represents a large portion of the resulting cost of these systems. Today, we have the results of a fully additive manufactured rocket injector with a demonstration in a relevant environment.” he said.