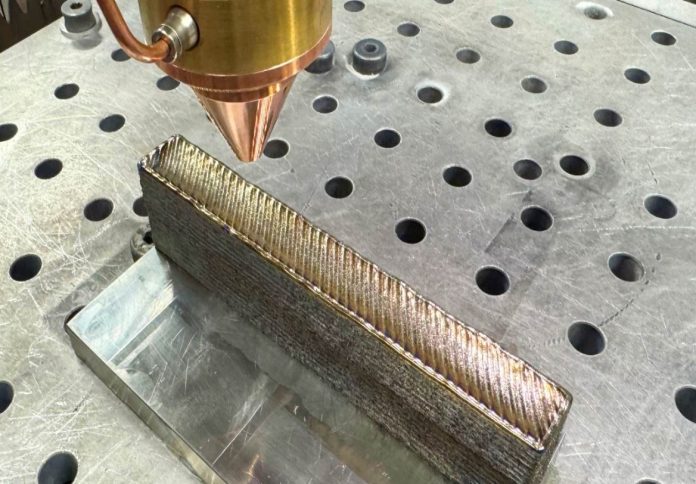

Engineers at RMIT University have developed a new type of 3D-printed titanium alloy that is approximately 29 per cent cheaper to produce than commonly used titanium alloys, marking what researchers describe as a significant advancement in additive manufacturing.

The breakthrough material, created by replacing costly vanadium with more readily available alternatives, was developed by researchers from RMIT’s Centre for Additive Manufacturing, as revealed in a news release.

The team has filed a provisional patent and is now exploring commercial applications, particularly in the aerospace and medical device industries.

Lead author and PhD candidate Ryan Brooke said the innovation could help shift the industry away from traditional alloys like Ti-6Al-4V, which are not fully optimised for 3D printing.

“3D printing allows faster, less wasteful and more tailorable production yet we’re still relying on legacy alloys like Ti-6Al-4V that doesn’t allow full capitalisation of this potential,” Brooke said. “It’s like we’ve created an aeroplane and are still just driving it around the streets.”

The new alloy demonstrates improved strength and ductility compared to standard options and prints with a more uniform grain structure, which enhances mechanical performance. This uniformity avoids the columnar microstructures often found in other 3D-printed metals, which can lead to uneven properties.

“By developing a more cost-effective formula that avoids this columnar microstructure, we have solved two key challenges preventing widespread adoption of 3D printing,” Brooke said.

“What I heard loud and clear from end users was that to bring new alloys to market, the benefits have to not just be minor incremental steps but a full leap forward, and that’s what we have achieved here.”

The research, published in Nature Communications, also presents a new framework for alloy design tailored to additive manufacturing. The study’s method streamlines the selection of alloying elements, enabling time and cost savings during development.

Professor Mark Easton, corresponding author and director at RMIT’s Centre for Additive Manufacturing, said collaboration would be critical in bringing the alloy to market.

“We are very excited about the prospects of this new alloy, but it requires a team from across the supply chain to make it successful,” Easton said. “So, we are looking for partners to provide guidance for the next stages of development.”

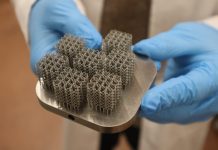

Samples of the new titanium alloy were produced and tested at RMIT’s Advanced Manufacturing Precinct. The study, titled ‘Compositional criteria to predict columnar to equiaxed transitions in metal additive manufacturing’, is available in Nature Communications (DOI: 10.1038/s41467-025-60162-0).