Researchers from Swinburne University of Technology are developing a 3D printing technology that uses earth, plant fibres and other natural materials to help address Australia’s housing shortage.

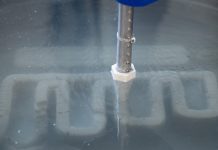

Led by Dr Mohamed Gomaa from Swinburne’s School of Engineering, the team is creating a 3D printing system capable of producing high-density fibrous-earth structures with precision.

The research aims to build stronger, more durable and sustainable homes at significantly lower cost and in less time, the university said in a news release.

“Earth is one of the oldest and most sustainable building materials we have,” Dr Gomaa said. “It’s abundant, recyclable and has almost no carbon footprint. By combining it with plant-based fibres and advanced robotics, we’re reimagining Indigenous building knowledge for a modern, digital era.”

According to the university, the technology could enable the rapid production of affordable housing, particularly in remote or disadvantaged areas where access to traditional building materials and skilled labour is limited.

It noted that by using locally sourced earth and plant fibres, the system has the potential to reduce construction costs and timelines by up to 60 per cent.

“With Australia expected to face a shortage of more than 600,000 social and affordable homes by 2036, we urgently need new solutions,” Dr Gomaa said.

“3D printing with earth offers a way to build faster, cheaper and with materials that are literally beneath our feet.”

The university explained that unlike conventional concrete construction, which contributes around eight per cent of global carbon dioxide emissions, the use of earthen materials has a near-zero carbon footprint.

The Swinburne team said the process enhances the strength and durability of earth-based mixtures by incorporating natural fibres from agricultural by-products such as hemp and rice husks.

“This approach not only improves the strength and resilience of the printed walls, but it also supports a circular economy by turning farming waste into something that can shelter families,” Dr Gomaa said. “It’s sustainable on every level – environmental, social and economic.”

The project involves collaboration between Swinburne, industry partner Luyten 3D, UNSW, and Indigenous knowledge holders who are contributing insights drawn from traditional earth-building techniques.

The team has already printed and tested small-scale prototypes and plans to move toward a full-scale demonstration build in Victoria to showcase the technology’s potential.

“What excites me most is seeing modern robotics breathe new life into ancient, sustainable materials,” Dr Gomaa said.

“Where I grew up, people lived comfortably in earth houses that had stood for centuries. Now, through 3D printing, we have the opportunity to take that same wisdom and make it part of the solution to today’s housing challenges.”

The research is supported by the Australian Research Council Linkage Projects Scheme.