Titomic Limited has entered into a strategic collaboration agreement with DNV, a global assurance and risk management company, to advance the certification of its cold spray additive manufacturing technology for applications in the maritime and oil and gas industries.

The collaboration aims to secure qualifications under international standards, including the NORSOK M-501, which governs surface preparation and protective coatings for offshore installations, Titomic said in a news release.

The standard, developed by the Norwegian petroleum industry, is considered a benchmark for corrosion-resistant coating systems used in harsh offshore environments.

The partnership also includes engagement with other classification bodies such as Lloyd’s Register, ABS, and Bureau Veritas.

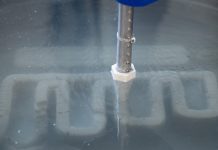

Titomic, known for its proprietary Titomic Kinetic Fusion process, says the agreement will support the validation of its advanced coating and repair technologies for use in environments where corrosion resistance and durability are critical.

“This agreement with DNV marks a significant step forward for Titomic as we expand into the global energy and maritime markets,” said Klaas Rozema, president of Titomic EMEA.

He added that achieving NORSOK M-501 and related certifications would enable the company’s technology to be used in thermal spray aluminium repairs, surface protection of field welds, and restoration of marine hulls, ballast tanks, subsea infrastructure, and pipelines.

The Titomic Kinetic Fusion process, which applies coatings without the use of heat, is promoted by the company as a safer and more efficient alternative to traditional welding and thermal spraying.

According to Titomic, the technology is suitable for use in remote and offshore locations, offering benefits such as reduced repair downtime, on-site applicability, and improved safety.

“This collaboration reinforces Titomic’s commitment to delivering practical, efficient, and reliable repair solutions for mission-critical infrastructure,” said Jim Simpson, CEO and Managing Director of Titomic.

He noted the technology’s material efficiency and capacity for rapid deployment as key advantages, particularly in cost-sensitive and high-risk environments.

The initiative is aligned with Titomic’s broader strategy to provide certified and sustainable solutions for infrastructure repair and maintenance.

The company aims to expand its role in global shipbuilding, offshore energy, and industrial asset management through technologies that support asset integrity and lifecycle extension.