The US Department of Defence through the Ukraine Security Assistance Initiative is set to provide Ukraine with seven WarpSPEE3D printers manufactured by SPEE3D, a Victoria-based additive manufacturing company.

These machines will be deployed near the frontlines, with a primary focus on the rapid production of critical repair parts for a variety of armoured platforms and aging military equipment systems.

This makes Ukraine the latest defence force to use SPEE3D technology to produce critical replacement “parts of consequence” in the field at the point of need, SPEE3D said in a news release.

“We’re focused on giving Ukrainian soldiers resources to fortify the maintenance and repair capabilities when and where it counts most. Our metal 3D printers will allow Ukrainian soldiers to manufacture metal parts at the point of need and in real-time so critical equipment can stay in the fight,” said Chris Harris, vice president of Defense for SPEE3D.

For example, during Project Convergence 2022, WarpSPEE3D showcased how its patented cold-spray technology can effectively support military supply chains.

In the harsh desert conditions of Fort Irwin, the SPEE3D and British Army team used WarpSPEE3D to print an M109 specialist tool at the request of the US Army.

This specialist tool was designed in just 9 minutes, printed in 30 minutes, and heat-treated in just under two hours, all while in the field. It was ready for use in as little as 3 hours.

The partnership with the British Army represents SPEE3D’s commitment to enhancing the supply chain operations of defence forces globally with advanced manufacturing technology (AM), according to the Australian manufacturer.

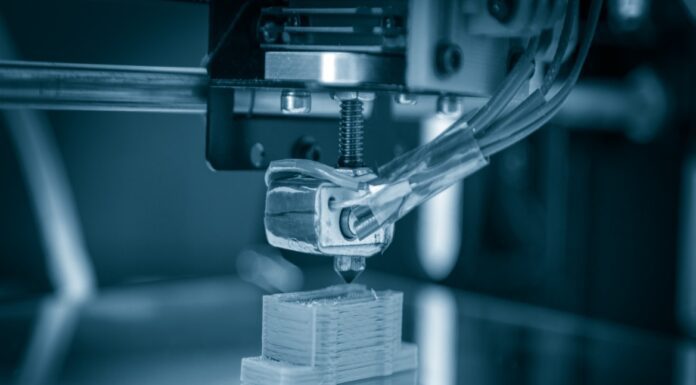

SPEE3D’s deployable metal 3D printers include WarpSPEE3D and XSPEE3D, which utilise patented cold-spray additive manufacturing (CSAM) technology, ideal for frontline environments as it does not rely on lasers or gases.

Instead, it utilises kinetic energy to bond metal particles together, resulting in the creation of the final part.

This unique method means WarpSPEE3D and XSPEE3D printers are exceptionally fast, energy-efficient, and capable of producing large parts of up to 1 meter in diameter or weighing up to 40kg, all while working with various metals.

The XSPEE3D was specifically engineered for military use, and developed in partnership with the Australian Army during their groundbreaking metal 3D printing field trials in 2020 and 2021.

Over a span of 15 days, the soldiers underwent rigorous training covering various topics, from engineering design theory to metallurgy and printer operation.

“By training Ukrainian soldiers and engineers to leverage metal 3D printing, we’re not only enabling them to print a part—we’re giving them tools to solve critical problems,” said Calum Stewart, Director of Defense Programs, EMEA.

He added, “This cutting-edge technology allows broken and damaged machinery to be repaired in hours – offering a significant advantage for Ukraine. Having WarpSPEE3D metal 3D printers in the country and readily available equates to a significant advantage when replacement parts are not accessible, which is often the case in theatre.”

SPEE3D and the Department of Defence will train soldiers to maintain and repair military equipment and salvage machinery.

As a result, military personnel will now have the ability to print parts of consequence, large and small, that could otherwise halt an advance or cripple an operation.

Deployable metal 3D printers can fabricate damaged parts quickly with the company’s proprietary and patented cold spray additive manufacturing (CSAM) technology.

Later this year, SPEE3D said the technology will also be trialled by the US Army for the DoD Point of Need Challenge.

The deployment of the company’s printers in Ukraine is expected to leverage the military readiness of the Ukraine Defence Forces supply chain.