Researchers from the University of Queensland have developed a new type of sinter capable of reducing carbon emissions in the iron and steelmaking industry.

Conducted by researchers in the university’s Sustainable Minerals Institute (SMI) in collaboration with Rio Tinto and Shougang Group, the project sought to create a novel sinter that can be less carbon-intensive to create and more efficient to use.

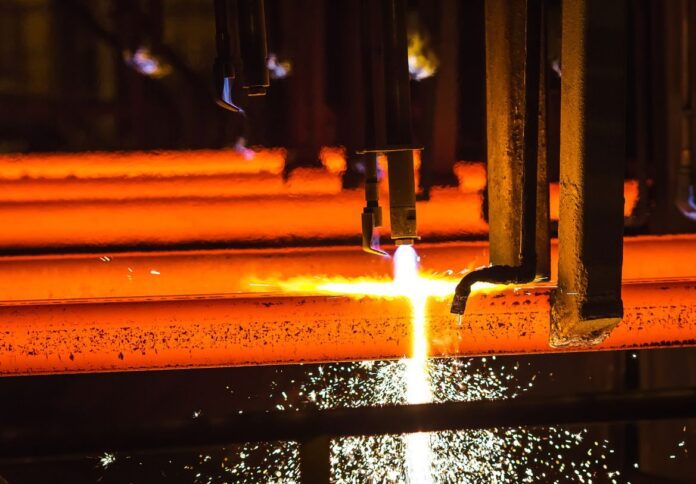

Sinter is used as the primary feed material for making iron in a blast furnace. It is created at a sinter plant by blending several materials, including very fine iron ore, into agglomerates under extreme heat to produce a more solid material that can be used in a blast furnace.

“When you talk about carbon and emissions, you are really talking about two stages: the emissions created when the sinter itself is made and then the emissions created by the furnace in which the sinter is used,” said Dr Xiaodong Ma, head of SMI’s High-Temperature Processing Program.

The new sinter, which is now the intellectual property of Shougang Group, addresses both stages but has a particularly significant effect on the amount of coke consumed at the sinter plant, Ma explained.

“It can reduce the amount of coking coal in the sinter by about 23 per cent – that is a huge amount considering the volumes of sinter used by the industry,” Ma said.

The project is the latest in a series of initiatives that seek to bring together metal miners and metal makers, who are interested in better understanding their products and reducing carbon emissions, SMI said.

“Rio Tinto is the world’s second-largest iron ore miner and their technical marketing team want to know how their iron ore fines are being used, and to what affect, as well as helping with the downstream carbon emissions related to them,” Dr Ma said.

“The Shougang Group is the world’s ninth largest steel maker, and they are very interested in decreasing carbon emissions across their operations, while maintaining performance, as their industry is a major contributor to global emissions.”