UNSW Sydney researchers are using advanced manufacturing techniques to create 3D-printed marine habitats designed to restore oyster populations in Sydney Harbour.

The project, led by the School of Built Environment at UNSW Arts, Design & Architecture, has produced BioShelters – artificial reef structures made from recycled plastic moulds and a concrete mix containing crushed oyster shells.

Installed at the new Sydney Fish Market site in Glebe, the BioShelters aim to address habitat loss caused by decades of urban development along the harbour shoreline, UNSW Sydney said in a news release.

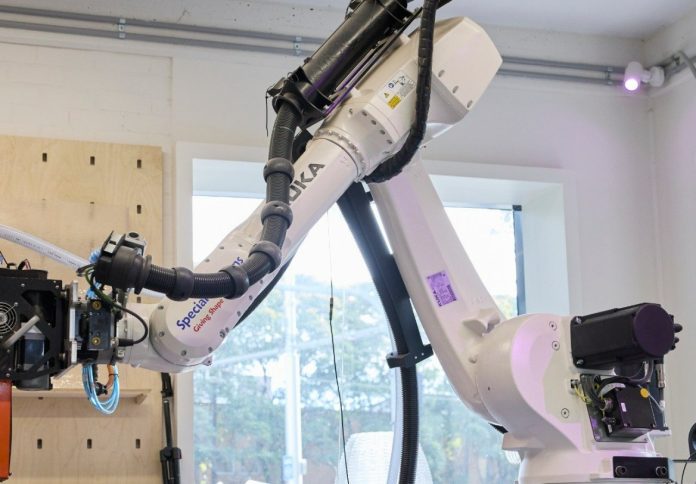

Professor M. Hank Haeusler, director of the ARC Centre for Next-Gen Architectural Manufacturing at UNSW, said the initiative applies manufacturing methods used in computational design and robotic fabrication to environmental challenges.

“Just as there is a housing crisis in Sydney for humans, there is one for sea creatures like oysters,” Prof Haeusler said. “What this project aims to do is create new artificial habitats that are as close to nature as possible.”

UNSW Sydney said each BioShelter measures six metres by two metres and stands 90 centimetres high, segmented into 25 panels. By incorporating reclaimed oyster shells into the build material, the structures provide a foundation for oyster colonisation and contribute to rebuilding marine ecosystems.

“We are using crushed oyster shells from the Fish Market as an aggregate in the concrete instead of pebbles or rocks,” Prof Haeusler said.

Oysters play a vital role in marine environments, filtering large volumes of water daily and supporting biodiversity. Marine biologist Nina Schaefer, who contributed to the project’s development, said the design had to replicate natural conditions.

“Filter-feeders rely on good water flow, algae need light and moisture, and mobile species like snails and crabs need places to hide,” she said. “The design had to accommodate water flowing through the structure and include features that trap water and offer shaded areas for shelter.”

The BioShelters differ from other coastal habitat projects by using algorithms and robotic fabrication to create site-specific designs.

“We use computation design that translates marine biology data to create 3D forms supporting a range of species,” Prof Haeusler said. “It not only restores oysters but also supports fish, seaweed, kelp and other native marine life.”

The concept originated in 2016, with specialists in architecture, marine biology and engineering collaborating to test prototypes.

A full-scale trial under the Anzac Bridge in 2020 showed the structures could successfully attract oysters, kelp, seaweed and small fish.

“The success of the proof-of-concept trial led to the commission from the new Sydney Fish Market to install and design the permanent feature,” Prof Haeusler said.

Looking ahead, the UNSW team plans to refine the fabrication process by printing directly in concrete to streamline production. Prof Haeusler said the goal is to expand the system globally.

“We want to develop a process where marine biologists can input site-specific information into a program, approve or modify the design, and then submit it for fabrication,” he said.

“We have already started conversations for a larger installation to revitalise seawalls across Sydney Harbour, and the principles could be applied to other species on land that also need homes.”