The US Naval Sea Systems Command (NAVSEA) has received complimentary reviews of the recently installed Markforged X7 field edition 3D printer on the Virginia-class submarine USS New Hampshire (SSN 778).

In a press release, NAVSEA said the 3D printer helps sailors maintain forward deployment by allowing crews to repair items such as pipe leaks and enclosures for new electrics in real-time, increasing self-sufficiency.

Capt. Bennett Christman, the commanding officer of USS New Hampshire, said that 3D printers provide the opportunity for creative problem solving, emphasising that “these devices lower the barrier for component manufacturing, empowering sailors to take ownership of their repairs, and to think outside the box.”

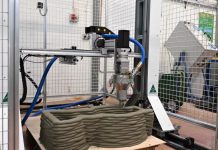

According to NAVSEA, the Markforged X7 3D printer was selected because of its dependability in a simulated maritime setting.

It was developed by NAVSEA’s AM Research and Development Programme (NAVSEA 05T) in collaboration with Naval Surface Warfare Center (NSWC) Philadelphia, NSWC Carderock, and Naval Undersea Warfare Center (NUWC) Newport.

“This system can be used to produce most of the currently approved Technical Data Packages that are available for Sailors on the Joint Technical Data Integration site,” said NAVSEA Additive Manufacturing Assistant Program Manager Lewis Shattuck.

Shattuck added that the fleet and NAVSEA engineers have identified these items to meet a range of needs, including routine or preventative maintenance, temporary replacements, quality-of-life products, drill props, tools, and fixturing.

The USS New Hampshire stated that even though the crew did not receive hands-on instruction on the Markforged X7 printer, the printer’s documentation was good and crew members with prior 3D printing knowledge were able to teach and mentor other crew members.

To create precise instructions for the Markforged X7, engineers from NUWC Newport, NSWC Philadelphia, and NSWC Carderock used knowledge gained from earlier 3D printer installations.

With the help of the instructions, sailors can independently configure the printer, print parts, carry out routine maintenance and calibration, as well as resolve issues.

To date, NAVSEA 05T, with support from engineers at NSWCs Carderock and Philadelphia, NUWC Newport, and Johns Hopkins Applied Physics Laboratory, said it already installed AM equipment aboard nine surface ships, including three aircraft carriers, and helped to inform the kit-based solution for additive manufacturing aboard four submarines.