Velo3D has entered into a Cooperative Research and Development Agreement with the US Army’s DEVCOM Ground Vehicle Systems Center to develop and qualify additively manufactured metal parts aimed at addressing supply chain challenges affecting ground combat vehicles and other military systems.

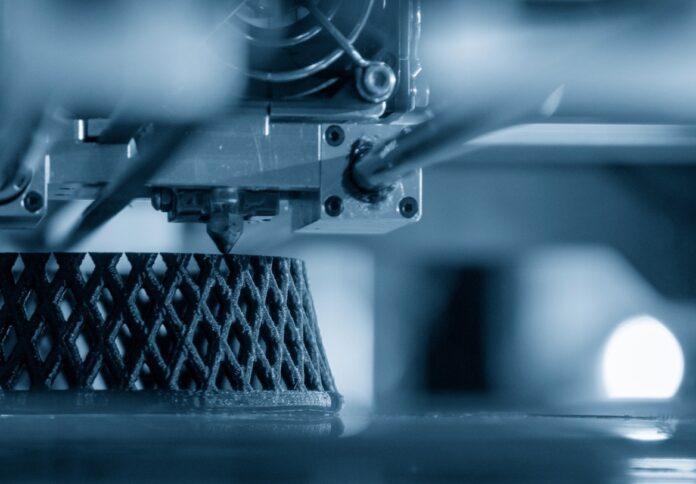

In a news release, the company said the agreement will focus on rapidly prototyping and qualifying complex parts and assemblies using additive manufacturing technologies.

According to Velo3D, once several prototype parts are successfully completed and qualified, the additively manufactured alternatives would be available for potential insertion into the US Army’s supply chain to help mitigate existing challenges.

“We are excited for this collaboration between GVSC and Velo3D to identify solutions that will rapidly improve the resilience to the Army’s combat vehicle supply chain,” said Brandon Pender, associate director of materials engineering at GVSC.

He said the combination of GVSC’s experience in advancing vehicle technology and Velo3D’s additive manufacturing capabilities is expected to support the Army’s operational needs.

The CRADA will leverage Velo3D’s Rapid Production Solution to explore alternatives to traditional subtractive manufacturing methods.

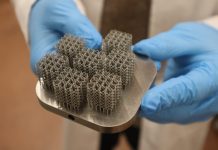

The collaboration also includes evaluating several Velo3D-qualified alloys for use with the company’s Sapphire family of printers, including large-format applications. Velo3D said its Rapid Production Solution is designed to enable scalable production of mission-critical parts and provide surge capacity when required.

Velo3D chief executive officer Arun Jeldi said the company views the agreement as an opportunity to contribute to defense manufacturing needs.

“Through our Rapid Production Solution, we are helping provide faster part delivery, enhanced reliability, and the surge capacity needed to meet evolving defense demands,” he said.

According to the company, its Sapphire printers are assembled in the United States and are capable of producing large metal components, while meeting US Department of Defense cybersecurity standards for secure network connectivity.