The International Manufacturing Technology Show 2014, the largest and longest running manufacturing technology trade show in the US, held annually at McCormick Place, is well under way in Chicago, Illinois.

This year’s event will run 8–13 September, attracting over 100,000 visitors from every level of industry and over 112 countries. IMTS is owned and managed by The Association for Manufacturing Technology (AMT).

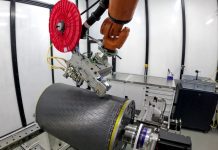

During the six day event, a whole vehicle, called the Strati, will be printed out over 44 hours and then rapidly assembled by a team led by Local Motors, the company revealed in a news release. The first drive will take place on 13 September.

The world is truly about to see what sustainable, digital manufacturing solutions can do. Local Motors’ Strati will be 3D printed in one place using direct digital manufacturing (DDM). This is the first time in history that DDM will be used to print a car.

“The Strati was designed by our community, made in our Microfactory, and will be driven by you. This brand-new process disrupts the manufacturing status quo, changes the consumer experience, and proves that a car can be born in an entirely different way,” said John B. Rogers, Jr., CEO of Local Motors.

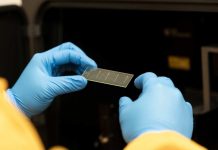

The project will be conducted in collaboration with the Energy Department’s Oak Ridge National Laboratory (ORNL) in Tennessee.

“This project represents the unique opportunity DOE’s National Laboratory System offers to the industry, to collaborate in an open environment to deliver fast, innovative, manufacturing solutions. These partnerships are pushing the envelope on emerging technologies, such as large scale additive manufacturing, and accelerating the growth of manufacturing in the United States,” said Craig Blue, Director, Advanced Manufacturing Program and Manufacturing Demonstration Facility at ORNL.

“The Strati will be showcased in AMT’s Emerging Technology Centre. The ETC was created to present manufacturing ‘technologies of the future’ from leading companies, universities, and government research labs. This feature returned IMTS to its roots as a forum where the latest technologies are first seen. This year is no exception, and we are confident that this will be the most exciting ETC effort yet,” noted Peter Eelman, Vice President – Exhibitions and Communications, AMT.

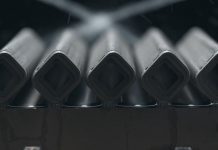

The car body is being printed in a machine made by Cincinnati Inc., a machine tool maker in Harrison, Ohio.

“The BAAM (Big Area Additive Manufacturing) machine can be used for actual production. The deposition rate of 40 pounds per hour of carbon reinforced ABS plastic and the large size mean that large parts, like a car, can be produced using additive technology,” said Andrew Jamison, CEO of Cincinnati Incorporated.

The printing has started and the vehicle is set to drive off the show floor this Saturday.