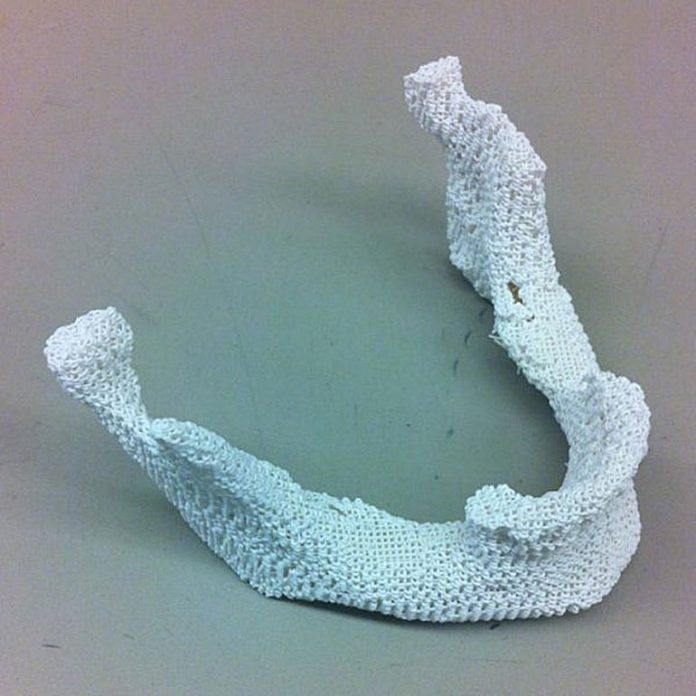

The need for replacement bones is enormous – an estimated 200,000 people need replacement implants due to surgery, trauma or birth defects.

Image credit: Johns Hopkins Medicine

In an effort to find a better solution than the ones currently available, a team of scientists at Johns Hopkins University have managed to create a new material that can be used to 3D print new bones.

According to the official announcement, the new material is a mixture of pulverised decellulised natural bone and polycaprolactone, a biodegradable polyester – the perfect combination of the strength and printability of plastic with the biological “information” contained in natural bone.

Polycaprolactone, or PCL, is a biodegradable polyester that is used for making polyurethane. Previous studies have shown that although strong, PCL doesn’t support the formation of new bone well so the scientists decided to combine it with “bone powder”.

“Bone powder contains structural proteins native to the body plus pro-bone growth factors that help immature stem cells mature into bone cells. It also adds roughness to the PCL, which helps the cells grip and reinforces the message of the growth factors,” said Warren Grayson, Ph.D., associate professor of biomedical engineering at the Johns Hopkins University School of Medicine.

As a natural progression, the team tested the printability of the new material. Using different amounts of the two components, they managed to find the perfect recipe.

“In the broth experiments, the 70 percent scaffold encouraged bone formation much better than the 30 percent scaffold,” says Grayson, “but the 30 percent scaffold is stronger. Since there wasn’t a difference between the two scaffolds in healing the mouse skulls, we are investigating further to figure out which blend is best overall.”

This new material can be used to 3D printing just about any shape of bone, completely eliminating the need to harvest bones from patients.