Tasmanian Oyster Co. will develop a new, game-changing laser etching system to identify and trace its products across global markets, a project that is expected to bring in an additional $3.5 million in revenues and create up to 25 new Australian jobs.

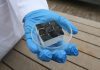

The new CO2-based laser etching process developed with the assistance of a co-funding grant from the Federal Government’s Advanced Manufacturing Growth Centre (AMGC) will allow the company to etch a brand mark or logo on the oyster’s shell, providing customers with peace of mind concerning the quality and provenance of the product.

This will help differentiate Australia’s highly prized Pacific oysters from the farmed items that make up 80% of the world’s oyster supply. Tasmanian Oyster Co.’s oysters thrive in nutrient-rich waters in the company’s growing regions along the island’s east coast and are some of the few that can be consumed direct from the ocean due to pristine growing environments

Simon Rechner, Project Manager at Tasmanian Oyster Co. said, “Probably one of the biggest challenges is being able to distinguish our product from others, either here or in export markets. AMGC helped us expand our thinking to export markets.”

“We think Australian oysters are some of the best in the world, but being able to market overseas is very difficult. An oyster sold in Singapore, Japan and Australia, without something on it to say where it comes from, could be from anywhere – our new technology changes that and gives us a great opportunity post-COVID to grow our brand,” said Rechner.

It is estimated the solution will increase the “product to price density” by $5 per dozen oysters sold, add $7 million to the Tasmanian oyster industry through the new authentication and marketing possibilities, and provide a $3.5 million increase in revenues to Tasmanian Oyster Co. through an estimated 25% growth in exports.

Managing Director of AMGC, Dr Jens Goennemann said opportunities for Australian manufacturers lie in competing on value not cost and brand Australia is in high demand right now.

“What Tasmanian Oyster Co. will do is add value to their product through the adoption of advanced technology, while also being able to highlight the country of origin for their products,” Dr Goennemann said.

“In developing this new technology Tasmanian Oyster Co. will also streamline shellfish processing, open up the greater export potential for their products and, possibly, even exports of the new technology.”

Tasmanian Oyster Co.’s new technology will be rolled out to Tasmanian oyster growers, helping them present “a united front” in export markets. It will then be offered to growers in other states within the $112 million Australian oyster market and possibly other shellfish lines.

Successful completion of the project is expected to generate an additional twenty Australian jobs across the engineering, manufacturing, sales and service disciplines in the long-term.

For further details of the project, partner organisations and funding arrangements visit – https://www.amgc.org.au/project/automation-of-oyster-packaging-and-certification-of-provenance/