Desktop Metal, a manufacturer of 3D printers that utilise metal and carbon fibre materials, has completed acquisition of EnvisionTEC, a leading global provider of volume production photopolymer 3D printing solutions for end-use parts.

The transaction, valued at $300 million, will see EnvisionTEC operate as a wholly owned subsidiary of Desktop Meta, with founder Al Siblani to serve as Chief Executive Officer of the EnvisionTEC business.

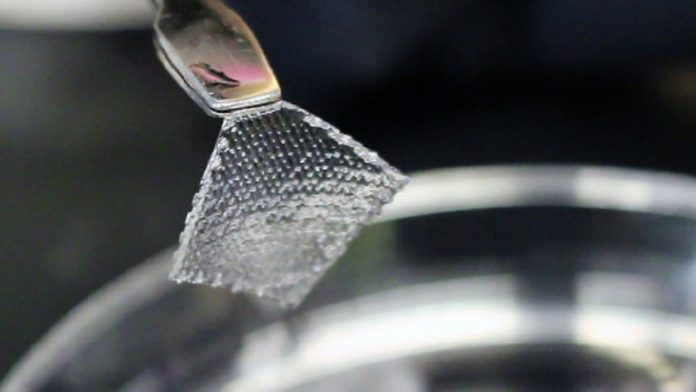

EnvisionTEC – the original inventor of digital light processing (DLP) 3D printing technology – has one of the strongest intellectual property portfolios in the area-wide photopolymer 3D printing market, counting more than 140 issued and pending patents.

The company has in excess of 190 qualified materials for its platforms and more than 5,000 customers across a broad range of industries, including automotive, aerospace, medical devices, jewellery, and biofabrication.

EnvisionTEC is also a leader in the dental market, with over 1,000 dental customers now using its printers for pre-production and end-use parts in this segment.

Ric Fulop, CEO and co-founder of Desktop Metal, said EnvisionTEC also brings a compelling product portfolio for photopolymer additive manufacturing under Desktop Metal’s umbrella, as well as its robotic additive manufacturing (RAM) digital casting capabilities, which it plans to significantly advance using its proprietary and patent-pending Single Pass Jetting technology.

“With EnvisionTEC now a part of Desktop Metal, we are well positioned to offer customers a complete platform across polymers and metals, focused on Additive Manufacturing 2.0 solutions for volume production of end-use parts,” Mr Fulop said.

“Together, we have more than 200 distribution partners around the world that extend our reach into applications across fast-growing markets for additive manufacturing, such as dental, medical, and jewellery, in addition to doubling down on the broader industrial market.

“As we join forces, I’m more confident than ever we can accelerate the adoption of AM 2.0 and help customers transform how parts are made around the world.”