Media Release

Silicon carbide (SiC) Schottky diodes are small semiconductor devices – one-way electronic switches – used in many power conversion systems. Due to their incredible thermal conductivity, high switching performance and efficiency, they are highly sought-after for applications such as solar inverters, motor drives, electric vehicle (EV) chargers and uninterruptable power supplies.

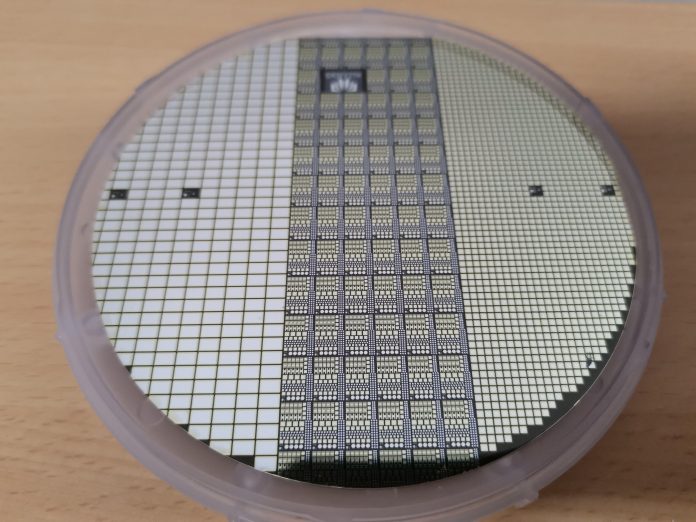

A research collaboration led by Queensland Semiconductor Technology Pty. Ltd. (Questsemi) and Griffith University, supported by Semefab Scotland and the Innovative Manufacturing CRC (IMCRC), is currently establishing the manufacturability, performance, and characterisation of SiC Schottky diodes at a wafer level.

Using SiC wafers, researchers at the Queensland Microtechnology Facility (QMF) of Queensland Micro- and Nanotechnology Centre (QMNC) at Griffith University, have developed a new technology that allows for more efficient and low-cost fabrication of SiC diodes.

“Manufacturing SiC diodes is complex and generally associated with high capital investment”, explains David Fletcher, Director at Questsemi.

“Unlike other SiC diode manufacturing processes, the technology developed by Griffith researchers uses steps that are common to standard Si wafer processing and thus dramatically simplifies the manufacturing process and associated costs.”

“With the funding support of IMCRC, we are able to trial production and accelerate the commercialisation of the new SiC technology which is set to improve the overall cost of semiconductor devices used in energy efficient technologies”, says Fletcher.

As part of the research project, valued at $1.3million, a pilot production facility will be set up at QMF to support the commercialisation of the technology. Devices necessary for the initial commercial product supply will be manufactured there.

Professor Sima Dimitrijev, who leads the research team, sees the development and pilot manufacture of SiC-based diodes at QMF as a great example of advanced-manufacturing collaboration.

“We are working with local manufacturers, which enables Questsemi not only to fast-track commercialisation but also to design and manufacture semiconductor devices that meet local demand for applications such as EV battery chargers, drones, solar inverters, industrial motor drives, and high-frequency power converters.”

The insights and advancements made throughout the project, will help Questsemi transition to volume manufacture of SiC Schottky diodes – locally and overseas.

IMCRC Innovation Manufacturing Manager, Dr Matthew Young points out that Questsemi’s collaboration with Griffith University demonstrates what is possible when a business research partnership sets out to push technological boundaries to solve unmet industry needs.

“SiC Schottky diodes play an important role in the semiconductor value chain, a sector often described as global engine for technology, economic and social progress.

“Questsemi and Griffith University’s SiC technology will have a flow-on effect in the design, prototyping and fabrication of other semiconductor devices, creating new business opportunities for Australia.

“With IMCRC activate funding, we are able to fast track the commercial translation of this semiconductor research into next-generation energy efficient technologies,” says Dr Young.

Professor Nam-Trung Nguyen, Director of QMNC at Griffith University, adds that the project with Questsemi is an example of ongoing translational research activities with direct commercial impact.

“We have a strategic line-up of projects from fundamental research to commercial development that ensures rapid transfer of technologies developed at our centre to industry partners.

“We have been hosting three projects with IMCRC, which provides an ideal platform to our impact strategy toward end user benefits.”