3D Systems has announced that it has been awarded two contracts to develop aerospace and defence 3D printing manufacturing capabilities.

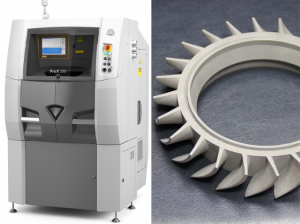

Valued at over $1 million, the contracts leverage the company’s proprietary Selective Laser Sintering (SLS) and Direct Metal 3D Printing (DMP) portfolio to meet the most demanding advanced manufacturing road map of the United States Air Force.

According to the official press release, the company will develop “a precision closed loop and advanced manufacturing and monitoring platform, designed to deliver the accuracy, functionality and repeatability specifications demanded for flight worthy aerospace parts.”

Under the terms of the first contract, 3D Systems will join forces with University of Delaware’s Centre for Composite Manufacturing (UDCCM), Sandia National Laboratory (SNL) and Lockheed Martin Corporation (LMCO) to integrate predictive technologies with its SLS 3D printers to dynamically monitor parts at the layer level during the manufacturing process, ensuring optimum accuracy and repeatability of manufactured aerospace parts.

Under the terms of the second contract, 3D Systems will collaborate with the Applied Research Laboratory of Pennsylvania State University, Honeywell International and Northrop Grumman Corporation to allow aerospace and defence manufacturers to gain full control of every aspect of the direct metal manufacturing process at the layer level, delivering fully dense, chemically pure, flight worthy metals parts.

“These important research projects will position leading industry manufacturers to 3D print high-performance precision parts at convincing scale with enhanced functionality. 3D Systems pioneered the use of advanced manufacturing for aerospace and defence applications and is proud to work with such esteemed partners to further advance these technologies and meet and exceed the future demands of the Air Force,” said Neal Orringer, Vice President of Alliances & Partnerships, 3DS.

Both projects will begin in the coming months and will be administered by America Makes (the National Additive Manufacturing Innovation Institute) and funded by the Air Force Research Laboratory (AFRL).

“The collaborative and forward looking initiative of America Makes members is driving extraordinary strides in 3D printing centric advanced manufacturing for this important industry,” commented Ralph Resnick, America Makes founding director and executive director.

“America Makes is grateful for the support and funding from AFRL to enable important research like this.”