Image credit: Melissa Osgood/Cornell University

A Cornell University group led by Robert Shepherd, assistant professor of mechanical and aerospace engineering and principal investigator of Organic Robotics Lab, has devised a way for a soft robot to feel its surroundings internally, just like humans do.

Image credit: Melissa Osgood/Cornell University

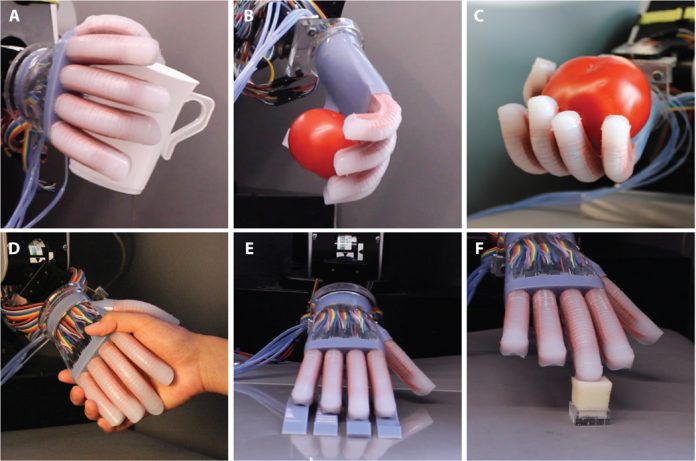

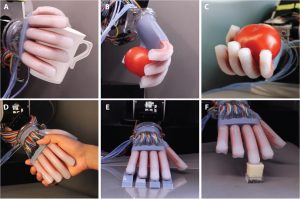

The group has published a paper detailing how stretchable optical waveguides act as curvature, elongation and force sensors in a soft robotic hand.

“Most robots today have sensors on the outside of the body that detect things from the surface,” said Doctoral student Huichan Zhao, the lead author of “Optoelectronically Innervated Soft Prosthetic Hand via Stretchable Optical Waveguides,” paper which is featured in the debut edition of Science Robotics.

“Our sensors are integrated within the body, so they can actually detect forces being transmitted through the thickness of the robot, a lot like we and all organisms do when we feel pain, for example.”

Optical waveguides have been in use for more than 40 years for numerous sensing functions, including tactile, position and acoustic. Initially, the fabrication process was somewhat complicated, but advanced over the last two decades.

The team employed a four-step soft lithography process to produce the core (through which light propagates), and the cladding (outer surface of the waveguide), which also houses the LED (light-emitting diode) and the photodiode.

Mr Shepherd noted that the more the prosthetic hand deforms, the more light is lost through the core. He said that variable loss of light, as detected by the photodiode, is what allows the prosthesis to “sense” its surroundings.

“If no light was lost when we bend the prosthesis, we wouldn’t get any information about the state of the sensor. The amount of loss is dependent on how it’s bent,” he added.

He said the optoelectronic prosthesis was able to perform a variety of tasks, including grasping and probing for both shape and texture. Most notably, it was able to scan three tomatoes and determine which was the ripest based on their softness.

According to the research team, the technology has the potential to be used to power prosthetic hands that restore people’s sense of touch.

This work was supported by a grant from Air Force Office of Scientific Research. The group worked at Cornell NanoScale Science and Technology Facility and the Cornell Centre for Materials Research, both of which are supported by the National Science Foundation.