The series is presented by

The fourth industrial revolution promises a paradigm shift to industry and society. The combination of cyber-physical systems (CPS), the internet of things (IoT), industrial internet of things (IIOT), cloud computing, cognitive computing, and artificial intelligence has created disruption in the traditional methodologies associated with manufacturing. While this promises increased efficiency and profitability, change is always best mitigated with cogent change management processes. This involves research about the technologies, understanding their utility, and possible returns on investment. The step is essential in overcoming any organizational reluctance to adopt change.

This last part of the series presented by Stratasys will outline the criteria and considerations for the adoption of 3D printing, one of the keystone technologies of the fourth industrial revolution, so as to ensure the possible outcomes for the adopter.

Common Perceptions of 3D Printing

There are several operational perceptions associated with 3D printing that might incite reluctance in this technology’s adoption. These originate from experiences associated with the first incarnations to 3D printers and these are as follow;

- Expertise

The perception of the advanced technology involved in 3D printing means that there is a widespread opinion that specialized technical expertise is required to operate a 3D printer. The perception was fueled by early 3D printers, according to Professor Brandt from the RMIT Advanced Materials Centre who noted the requirement for technical specialist CAD data into the 3D printer. - Functionality

Initial incarnations of 3D printers were used in very specific industries. The earliest adopters were biomedical and aerospace industries that required complex and customized shapes for their applications. As a result, the perception still persists that the utility of 3D printers might be minimal to other manufacturing segments. This is confirmed by maker spaces such as the Melbourne University Fab Lab, a maker space which noted that entrepreneurs in consumer manufacturing are often surprised when 3D printing is offered up as an option 1. - Expensive

The specific industries which first utilized 3D printing, coupled with the novel technology meant that early 3D printers were expensive to use and operate. This expense was also exaggerated by the meager early computing abilities of the interface which required increased expenditure on data processing. The perception of the expense still persists as the technology has advanced. - Reliability Issues

The operational complexity of early 3D printers and the untested novelty of the technology meant that early printers often encountered operational stoppages. This perception of unreliability was further compounded by the fact that CAD systems required to form designs did not possess user-friendly interfaces. Troubleshooting was therefore time-consuming and expensive. This particular impression persists from those who observed the technology in its initial forms.

Modern 3D Printing

Current 3D Printing, however, has been improved and customized in order to address those perceived issues.

- Ease of Operations

The research and development associated with computing have resulted in improvements to user interfaces. These improved user interfaces mean that most modern 3D printers are able to directly link to the design software without any intermediate software.

Figure 1. Data transmission for 3D Printing 2 Since most designers are well versed with design software, operating the printers would not require much retraining. Most 3D printers are also able to produce sophisticated products while being self-contained and self-operated. This means the printers can be made to be portable and connected to existing computers without having additional hardware and software which boosts integration.

- Widespread Utility

The usage of 3D printers has exploded across all fields of manufacturing. The ubiquity of 3D printing in modern manufacturing can be seen from the chart below from a PWC analysis of 3D printing which shows the increased uptake of 3D printing technology among the various industry sectors.

Figure 2. PWC analysis of 3D printer market growth in various sectors 3 The applications of rapid prototyping and iterative problem solving have become the norm in all manufacturing segments in conjunction with a greater focus on innovation and change. This also means that 3D printing has a place in all manufacturing and R&D institutions notwithstanding the applications.

- Revenue Generation

Expenses associated with 3D printing are actually less than those associated with traditional manufacturing methods such as injection at lower volumes as shown by the chart below.

Figure 3 Cost comparison with breakeven point 3 Given the intent to use 3D printing for prototype generation, low volume production is a viable paradigm for 3D printing

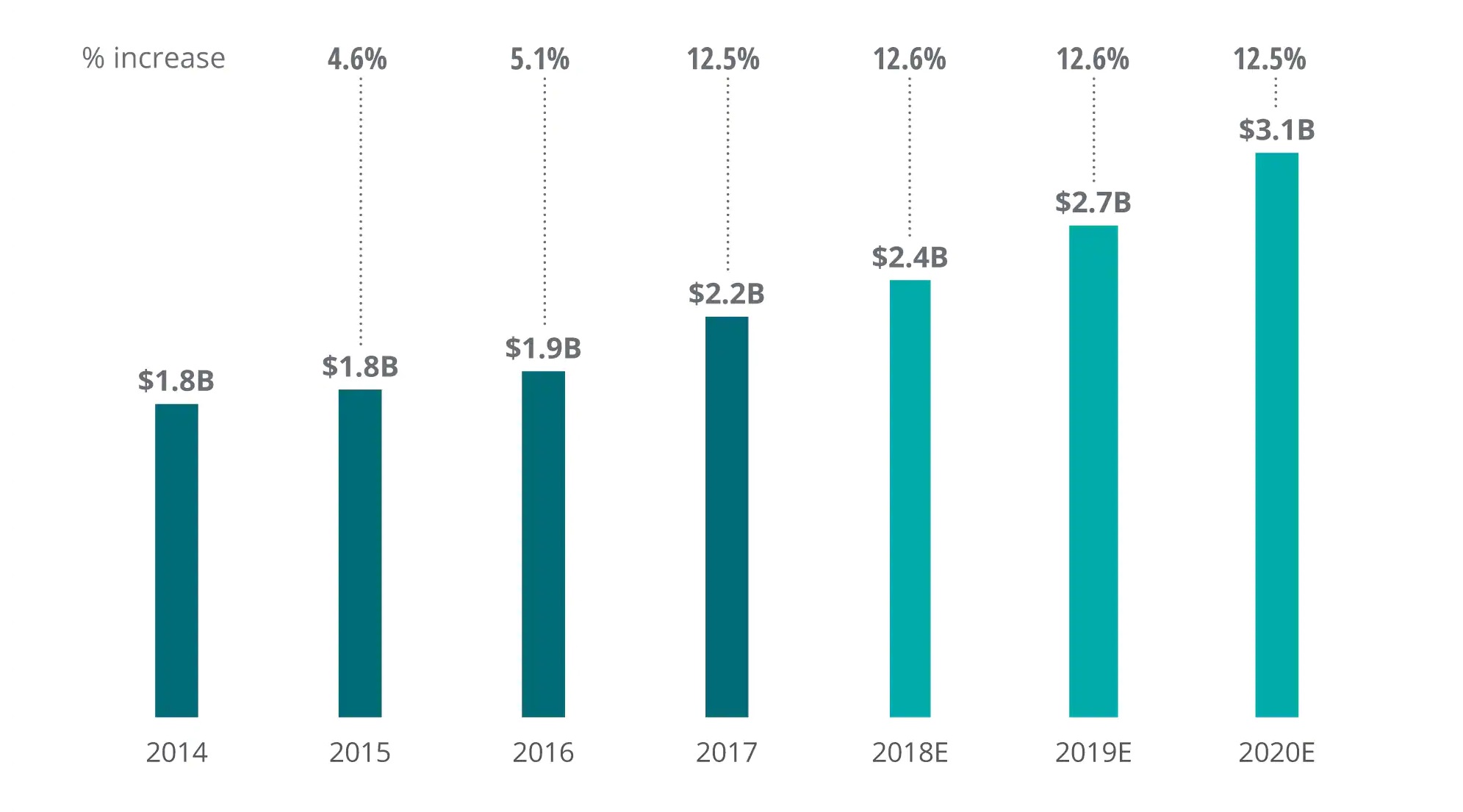

This relatively low expense is further compounded by increased revenue observed by organizations that have adopted 3D printing. Decreased product life cycles and better quality prototyping have led to impressive revenue gains as seen in the chart below.

Figure 4. Revenue growth from 3D printing 4 As such, even initial expenses that might be incurred in the adoption of the technology is ameliorated by increased revenue.

Considerations before investing

There are therefore three main considerations for anyone considering integrating 3D Printing into their daily operations.

- Quality of Product

Despite the improved overall quality of 3D printing, the level of reproduction and complexity varies greatly with several factors. The two prototypes below, for instance, show the differing quality from two different 3D printers.

Figure 5. Benchmarking Tool, 3D Printers 2 The quality is determined by factors such as the dimensions of precision that the printer is able to detect. This resolution factor, however, has to be combined with effective temperature control to ensure effective setting and tempering of the final printed product. The quality also depends on the flexibility of material types that can be supported on the printer. Unsupported material types will yield less than ideal products and it is important to choose a 3D printer that can manufacture prototypes in many material types.

- Integration CapabilitiesUser interfaces have improved to the point of “plug and play” capabilities. This means that more advanced 3D printers can be directly connected to existing organizational infrastructure to seamlessly produce prototypes. The increased portability of 3D printers also means that it is no longer necessary to have them on the production floor. More advanced printers could be installed in office settings improving the rate of rapid prototyping and the product cycle as well. The integration into the existing office

infrastructure is therefore of importance to reap the maximum benefit. - Ease of OperationsThe most advanced 3D printers on the market invest in making the production system self-contained and user-friendly. This includes the ability to use open source or existing design software to generate CAD designs for the printer. Another major consideration would be the speed of production. Since the intent of the 3D printer is to speed up the production cycle, it is necessary for new adopters to find out what the normal rates of production for the particular printer.The final operational consideration would be to determine the extent of support required from the 3d printer manufacturer/retailer in order to have seamless operations. Ideally, the 3D printer selected should be self-contained with minimal expertise required to operate. This would also translate into a reduction of maintenance.

Stratasys’ new line of industrial design 3D printers, the F123 series falls within the considerations mentioned and should be considered for anyone beginning their 3d printing journey. The series is portable with plug and play capabilities to seamless integrate with existing office infrastructure. It is also far more sophisticated than tabletop 3D printers with an increased production resolution, precision, and ease of operations. Stratasys, which pioneered the Fused Deposition Methodology has also been the expert in 3D printing for more than a decade and is a trusted provider of hardware. To find out more, refer to the link below to access a webinar about industrial 3D printers.

What is Industrial Grade 3D Printing?

1 Melbourne University, 2019, FabLab experiences, https://edsc.unimelb.edu.au/maker-spaces/fablab,retrieved 24/09/20192 Azimi, Parisa & Benzel, Edward. (2016). 3D Modeling and Printing Technologies in Neurosurgery. International Clinical Neuroscience Journal. 3. 175-176. 10.22037/icnj.v3i4.16129.

3 Van der Straeten,J., Vannacker, A., 2019, A cost perspective on 3D printing, PWC Insights, https://www.pwc.be/en/news-publications/insights/2017/cost-perspective-3d-printing.html, retrieved 24/09/2019

4 Stewart,D, 2018, December, 11,3D printing growth accelerates again, Deloitte Insights, https://www2.deloitte.com/us/en/insights/industry/technology/technology-media-and-telecom-predictions/3d-printing-market.html, retrieved 24/09/2019