Livium Ltd has commenced engagement with rare-earth element (REE) extraction technology developers, as part of its strategy to broaden its role in the circular economy and complement its core business in battery and e-waste recycling.

The company is in discussions with both Australian and international developers of REE technologies, identifying the sector as a high-growth opportunity in line with Livium’s expertise in resource recovery and sustainable materials production, as revealed in an ASX announcement.

“Rare earth elements are essential to power technologies that are driving the energy transition, yet global supply chains remain vulnerable to ongoing geopolitical shifts,” said Livium CEO and Managing Director Simon Linge.

“By actively pursuing options to commercialise REE extraction technologies, we are strategically positioning Livium to meet this growing demand while remaining anchored in our strengths in resource recovery and process innovation.”

Rare-earth elements are vital to clean energy and advanced electronics, commonly sourced from end-of-life products such as electric motors, magnets, and e-waste.

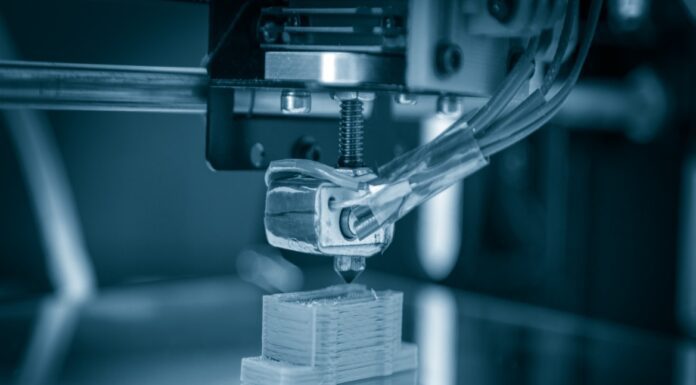

Extraction techniques – including hydrometallurgy, pyrometallurgy, solvent extraction, and emerging biotechnological processes – enable the reuse of these materials with a reduced environmental footprint compared to primary mining.

Livium sees the expansion into REE as a logical progression for its wholly owned subsidiary, Envirostream, which already performs front-end processes such as shredding, grinding, and magnetic separation.

The company noted that Envirostream is already linked to REE-rich waste streams through its partnerships with clients in clean energy and e-mobility sectors.

The global market for REE is projected to reach US$9.6 billion by 2026, with recycling expected to play a growing role in meeting demand amid calls for supply diversification and environmental stewardship.

Alongside its exploration of REE opportunities, Livium is also in advanced talks to license its proprietary cathode powder manufacturing process (VSPC) in jurisdictions outside its core regions.

The VSPC process combines solid-state and solution-phase synthesis to produce lithium ferro phosphate (LFP) and lithium manganese ferro phosphate (LMFP) powders, which are used in battery applications.