Johns Hopkins University Applied Physics Laboratory (APL) and the Naval Sea Systems Command (NAVSEA) are partnering to advance the use of additive manufacturing, or 3D printing, in the production of critical military components, aiming to increase trust and standardisation in the technology for naval applications.

According to Johns Hopkins, while additive manufacturing has gained ground across industries, its adoption in military contexts has been slowed by concerns over consistency, reliability and material strength.

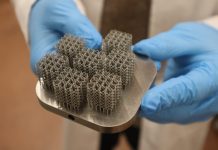

Johns Hopkins APL, based in Laurel, Maryland, is addressing those concerns through research and development in laser powder bed fusion – a precise metal 3D-printing process – with results that NAVSEA sees as essential to the future of fleet maintenance and design.

“Most of the previous literature painted a picture of inconsistency,” said Michael Presley, an additive manufacturing engineer in APL’s Research and Exploratory Development Department.

“What we’ve shown through rigorous research is that as long as you control your feedstock, process parameters and post-processing, you can get highly consistent material properties.”

Presley and fellow researcher Eddie Gienger have led studies confirming that the technology can meet the high-performance demands of military use. Their work includes analyses showing how to eliminate porosity in printed metals, ensure mechanical properties across vendors, and maintain durability over time.

Gienger emphasised the operational importance of these findings: “The expected service life of a Virginia-class submarine is 33 years. NAVSEA must have confidence in the lifespan of additively built components compared to those manufactured with traditional processes.”

Standardisation has become a priority for NAVSEA as it looks to scale additive manufacturing across its supply chain.

“We don’t just need additive manufacturing to work – it needs it to work predictably,” said Justin Rettaliata, NAVSEA’s technical lead for additive manufacturing. “To scale up, we need a mature industrial base that can produce additively manufactured parts at consistent quality levels across vendors and environments.”

APL has contributed directly to NAVSEA’s official manufacturing and certification guidelines, cutting machine certification requirements by over 60% while maintaining high reliability standards.

Presley noted, “Instead of requiring 300 test samples and millions of dollars in qualification costs, we helped streamline the process into something practical yet robust.”

The partnership has already yielded operational benefits. A recent deployment saw an amphibious Navy ship suffer a material failure in a component that could not be sourced quickly.

In response, APL and the ship’s crew reverse-engineered the part and manufactured a replacement using wire-laser directed energy deposition — all within five days.

“That’s what success looks like,” said James Borghardt, program manager for Maritime Expeditionary Logistics in APL’s Force Projection Sector. “Reducing logistics delay time from months to days is a game-changer for operational availability.”

Looking ahead, the team sees greater promise in integrating additive manufacturing into the design of new mission-critical systems.

“Success means a world where we are leveraging additive manufacturing not just for crisis fixes but for primary design and construction,” Rettaliata said. “We’re not quite there yet, but our work with APL is getting us closer every day.”