Researchers at Arizona State University are working to enhance metal 3D printing processes through the development of artificial intelligence systems designed to improve the speed and reliability of producing critical components, including naval propellers.

The project is being led by faculty members from the School of Computing and Augmented Intelligence within the Ira A. Fulton Schools of Engineering, with a focus on addressing ongoing challenges in accurately predicting the strength and durability of 3D-printed metal parts.

Backed by a grant from the National Science Foundation, professors Aviral Shrivastava and Ashif Iquebal are spearheading the project titled “CompAM: Enabling Computational Additive Manufacturing.”

The researchers are using AI to predict how metal microstructures form during the printing process, significantly reducing the time and computational resources needed compared to traditional simulation techniques.

“When we do metal printing, the quality of metal is actually dependent on the cooling curve,” said Shrivastava, a professor of computer science and engineering. “We want to control cooling so we can achieve the desired properties.”

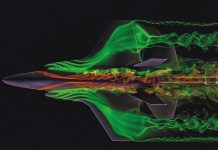

The team is focusing on a demonstration involving a five-axis 3D-printed naval propeller made from 316L stainless steel, a commonly used industrial-grade alloy.

The complexity and performance demands of such a part make it an ideal test case for pushing the limits of current additive manufacturing technologies.

A major hurdle in metal 3D printing is controlling the material’s microstructure, which can vary drastically based on subtle changes in heat or timing during the printing process.

This issue mirrors techniques used in traditional blacksmithing, where different quenching methods yield different metal properties.

To avoid the costly and time-consuming process of trial and error or slow simulations, the ASU team is developing a physics-informed AI model that learns how metals behave during printing.

The system integrates fundamental equations from physics with data-driven approaches to make more efficient and accurate predictions.

“For many processes, there are actually a lot of studies that have been done,” Shrivastava explained. “Physics is just a set of rules that are obeyed in the real world. What we’re doing is taking these equations and combining them with data-driven learning to make the system learn better and faster.”

The system is designed to focus computing resources where they matter most – on parts of the material that are changing rapidly – and skip over more stable regions, which further accelerates the process.

Assistant professor Ashif Iquebal, whose expertise lies in smart manufacturing, emphasized the real-world potential of the research.

“The real value of this work is its ability to bridge research and industrial need,” Iquebal said. “In industries like aerospace, defense and energy, the performance of metal components isn’t negotiable — it’s mission-critical. By giving manufacturers faster, more accurate tools to predict and control material properties, we’re enabling a new era of precision manufacturing and reducing the costly guesswork that often slows innovation.”

The project is supported by a state-of-the-art 3D printer housed at the ASU Innovation Hub, featuring a six-axis robotic arm and laser capabilities.

The team will use it to print the naval propeller and validate the AI system’s predictions against traditional simulations and actual results.

The tools and software developed in the project will be made freely available, allowing other researchers to benefit from faster simulations.

The team also plans to integrate the work into graduate-level computer science courses and conduct K–12 outreach activities.

Ross Maciejewski, director of the School of Computing and Augmented Intelligence, said the project showcases the strength of interdisciplinary collaboration.

“This project represents exactly what we strive for — innovation that’s deeply relevant to industry,” Maciejewski said.

“By combining artificial intelligence with materials science, our faculty members are charting a new course for advanced manufacturing. It’s a demonstration of how our research is propelling the future of engineering.”