It is becoming more apparent that researchers are pushing the boundaries of medical science as additional knowledge about the nation’s efforts in bioprinting continues to surface.

Australia’s biotechnology sector has prospered for years as trailblazing researchers advance their discoveries.

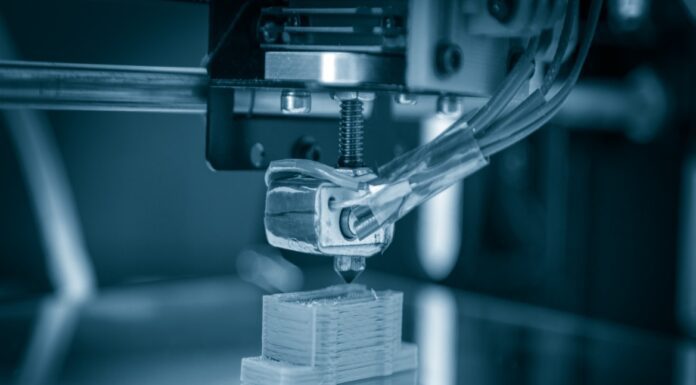

Researchers at the University of Sydney and the University of Technology Sydney (UTS) are pioneering research and development in the area of artificial bioprinting, which has the potential to revolutionise organ transplantation in the coming decades.

Thus, this work is laying the foundation for the future of medical science.

Lab-made lungs

The University of Sydney’s researchers have created a step-by-step guide for building sophisticated human lung models in the laboratory, which they claim would speed up the discovery and development of novel medications and lessen the need for animal testing.

The study, which will be published in Biomaterials Research, was conducted by Dr Huyen Phan of the University of Sydney and colleagues from Australia, South Korea, and China.

Organoids, also referred to as “mini organs,” are 3D structures created in the laboratory that resemble actual organs in the body, and they act as an evaluation site for biomedical research.

Commenting on the study, senior author Wojciech Chrzanowski, Professor of Nanomedicine in the Sydney Pharmacy School, Faculty of Medicine, and member of the Charles Perkins Centre, said, “We decided to build two different lung models, one which mimics phase one clinical trials; a healthy lung to study the safety of new drugs.”

Chrzanowski added, “The other one mimics phase two trials, a diseased lung that, in our case, mirrors chronic obstructive pulmonary disease, enabling us to study the therapeutic effectiveness or superiority of the drugs.”

More accurate than traditional models

The models detailed in the paper, which are more accurate than conventional models, are special in their capacity to replicate the environmental circumstances of a human lung, according to Professor Chrzanowski. The team uses cells directly from patients to construct lung models that closely resemble actual lungs in the body.

Traditionally, the entire process of developing and obtaining regulatory approval for a new drug can take anywhere from 10 to 15 years or more, and it can cost hundreds of millions or even billions of dollars.

However, Chrzanowski suggests that when using organoid models, this timeline shrinks substantially.

Call for a national centre for medical research using non-animal methods

According to Chrzanowski, who has been advocating for the establishment of a national centre for medical research alternatives to animal methods, the development of these lung models places Australia at the forefront of mini-organ research.

Australia took a brave step by becoming one of the first nations to outlaw animal testing for cosmetics. A voluntary code of conduct for the cosmetics industry was already issued by the government in 1997, encouraging businesses to replace animal experimentation with other types of research. Then, in 2017, a law was established that forbade the sale of cosmetics that had undergone animal experimentation as well as the use of data from such testing for cosmetic purposes.

Transforming healthcare with the growth of the biotech industry

The lung models, according to Professor Chrzanowski, might have a significant impact on basic science, enabling the study of how various organs operate and how to create the most efficient therapeutic approaches.

The researchers said the huge advantage of their models are their reproducibility, reliability and the ability to conduct research in a cost-effective way at a large scale.

“They accelerate the process of discovery, they shorten the process of getting to clinics, but also substantially increase our confidence in the molecules we create before we go to clinical trials,” Professor Chrzanowski said.

The most recent in a long career of designing and creating nanomaterials for medical uses is Chrzanowski’s miniature lungs.

Additionally, the professor has investigated various aspects of bioprinting, including developing new biomaterials and optimising printing techniques to increase the precision and functionality of printed structures, as part of his larger work in the field of biomaterials science and engineering.