Online Laser Pty, an Australian laser subcontractor, has significantly enhanced its operational efficiency by integrating Lantek’s advanced sheet metal CAD/CAM and ERP software, resulting in a doubling of its manufacturing capacity.

Based in Bendigo, Victoria, the company previously operated with a now-unsupported proprietary system to manage its two Bystronic Bystar fibre lasers and streamline workflow.

Ben Harris, Programming and Production manager at Online Laser, noted the challenges faced with the old system, emphasising the need for a comprehensive solution that could seamlessly handle quotations, programming, and production processes.

The Lantek system, implemented in July 2019 and expanded this year with the addition of Lantek Opentalk connection, has revolutionised Online Laser’s operations.

The integrated Lantek Expert CAD/CAM, MES, Integra, and WOS offer a cohesive solution, automating tasks and significantly reducing time-consuming and error-prone data entry.

The Opentalk connection directly to the laser machines ensures automatic validation of machine status and part manufacturing.

One of the key advantages highlighted by Harris is the swift analysis of laser cutting times using the integrated Lantek Expert.

The system efficiently combines this data with subcontract costs, enabling the rapid generation of accurate job prices.

The ability to import CAD models directly into the Lantek software streamlines the process further.

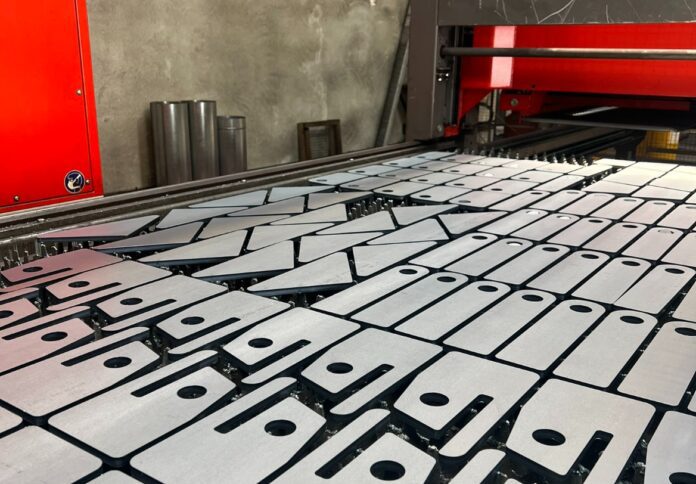

Online Laser now efficiently nests parts from different customers in the same sheet when material type and thickness align, optimising material usage.

The inventory system, a standout feature, allows the management of material remnants, preventing sudden shortages and reducing the need for frequent physical stock checks.

Additionally, the software automates the creation of invoices, delivery notes, and pallet labels, enhancing the overall workflow.

“The MES system and the real-time reporting from the machines gives us an accurate picture of delivery times. Everyone has visibility of the information, so we always give the customer consistent and accurate information on the status of their job,” Harris explained.

Harris also acknowledged the software’s role in ensuring transparency on costs, improved competitiveness, and enhanced operational efficiency.

The tailored Lantek Expert CAD/CAM software, with its customisable postprocessor, has been fine-tuned to suit Online Laser’s machines, showcasing adaptability for different laser machines and materials.

Ongoing support and training from Lantek and local support from Klugo in Australia and New Zealand have played a crucial role in the successful integration of the software.

Ben Harris concluded, “The software has definitely made the workplace a lot more efficient. We are a lot more transparent on cost, and we can see where the profit is, which was almost impossible before. It is a vital part of our operation making us much more competitive, faster, and efficient.”