Sponsored content by Schneider Electric

AVEVA™, a global leader in industrial software driving digital transformation, has partnered with Schneider Electric to redefine what smart, sustainable mining looks like in the age of AI.

Combining AVEVA™’s industrial software expertise with Schneider Electric’s leadership in energy management and automation, the collaboration combines real-time operational data with intelligent control systems to drive smarter, faster, and leaner mining operations.

Together, they enable operators to gain a complete view of the mining value chain, from pit to port, optimising energy use, predicting maintenance needs before failures occur, and accelerating project delivery through AI, digital engineering, and advanced analytics.

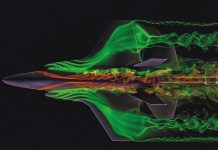

This connected, data-driven approach is transforming how mines manage energy and operations. By pulling live data from multiple systems, operators can quickly identify inefficiencies and respond in real time, from shutting down idle conveyors to optimising ventilation or adjusting mill speeds.

AI and advanced analytics can also recommend optimal equipment settings to minimise energy use without compromising output.

As the demand for critical minerals such as lithium, nickel and copper accelerate, miners are under increasing pressure to improve efficiency, cut carbon emissions, and operate with greater predictability.

Through their combined capabilities, AVEVA™ and Schneider Electric are enabling mining organisations to operate with greater intelligence, moving from reactive to proactive decision-making that optimises resources and reduces emissions.

“Digital integration is transforming how mines are designed, built and operated”, said Glenn Kerkhoff, Global Industry Principal, Mining, Metals & Minerals at AVEVA™. “By uniting data across assets, energy systems and supply chains, we’re enabling miners to scale faster, reduce emissions and improve productivity, all while maintaining the highest standards of safety and compliance”.

Through the partnership, Schneider Electric and AVEVA™ have helped leading mining operators achieve tangible business and environmental gains:

- Newmont achieved a $1.5 million annual fuel saving at its Papua New Guinea site by integrating real-time data analytics with energy and equipment management systems.

- Rio Tinto deployed a suite of digital tools to drive greater efficiency, transparency and control across mine development projects, cutting engineering time and capital expenditure while improving predictability and control.

These results reflect how data-led insights are being used to reshape traditional mining processes, driving higher performance with lower impact. According to McKinsey & Company, digital technologies and advanced analytics could generate up to US $290 billion in added value for the global mining and metals sector by 2035, underscoring the scale of opportunity for data-driven transformation.

Looking ahead, the next wave of digital transformation will see AI and automation converge with electrification to create fully autonomous, low-carbon mines.

From connected pit-to-port ecosystems to remote operation centres, and mobile fleets, data-driven decision making will underpin safer, more efficient, and more sustainable production across the global mining value chain.

“Digital transformation in mining is no longer about technology for its own sake, it’s about building resilience, competitiveness and responsibility,” said Carlos Urbano, Vice President, Industry, Schneider Electric.

“Together with AVEVA™, we’re helping the industry reimagine how mines are powered, controlled and optimised for the energy transition. By combining electrification, automation and intelligence, we’re creating operations that are not only efficient and safe, but fundamentally more sustainable and future-ready.”

Together, AVEVA™ and Schneider Electric are empowering the mining industry to achieve the next frontier of operational intelligence. By integrating AVEVA™’s PI System™, Predictive Analytics, Production Management (formerly AMPLA), Asset Information Management (AIM) and Unified Engineering solutions CONNECT industrial intelligence platform with Schneider Electric’s EcoStruxure™ platform to drive efficiency, reliability and sustainability across mining operations.

This article contains information provided by Schneider Electric and is intended for general use only. It does not take into account your personal, professional, or business circumstances. Please seek professional advice and review the product’s terms and conditions before making any decisions.