Media Release

CirPro (Australia), formerly Pirie Meats, have today signed an MoU with Siemens that outlines a number of areas of technical cooperation that will guide CirPro’s design and implementation of an advanced livestock processing facility planned for Port Pirie. With COVID-19 travel restrictions in place, the Chair and CEO of Siemens Australia, Jeff Connolly and CEO of CirPro, Reg Smyth, attended a virtual ceremony that formalised a relationship that has already started in support of detailed design.

“As a greenfield facility, we have the opportunity to efficiently incorporate leading technologies and smart infrastructure solutions from Siemens that will set us on the best path to establish a modern processing facility that is ready for Industry 4.0,” according to CirPro CEO, Reg Smyth. “This MoU with Siemens means that we have access to knowledge across the broadest spectrum of technology with a single technology company. What I really want out of this is to develop a view of what’s possible – and I can’t think of another company that could deliver the breadth and depth of knowledge and technology offerings that Siemens can,” he said.

“Embracing Industry 4.0 is critical as we prepare our competitive place in the world. But when it comes to business, what’s most important is the objectives such as speed, resource efficiency, flexible production, scalability, sustainability and so on. This is what drives competitiveness. When you look at this wholistically against the technology solutions available today in digitalization, automation and energy efficiency, you can achieve amazing outcomes. However, to really achieve maximum efficiency you need to include all aspects of the business end to end – everything from interactions with your supply chain to cyber security, smart building technologies and even types of skills needed to operate the plant,” said Mr Connolly.

At a recent event, CirPro announced collaboration plans that support reduction of methane emissions from livestock fed on a seaweed supplement that will be grown in South Australia through to integration of unique Australian processing technology that will support production of high-value materials suitable for human and medical use. The new processing lines will take material that has traditionally been low-value or not suitable for human use and optimise returns.

Smyth reinforced that, “Embracing Australian innovation and advanced plant technologies from Siemens in this way is exciting, but will present challenges and require collective commitments to support an industry transformation that will create new market opportunities for Australian products, greater resilience and increased returns to farmers through to value-add product manufacturers. Siemens support for comprehensive digitalisation and traceability across this new supply chain will be fundamental to informing and protecting the quality, integrity, value and future growth of all products that come through our new facility.”

On the issue of name change from Pirie Meats to CirPro, Smyth clarified that “traditional protein is a significant part of what we will deliver, but there is so much new product that we will create for many markets. The CirPro brand will enable us to more appropriately engage with nutraceutical, medical, food processing and cosmetic markets and manufacturers, and it represents our commitment to ‘circular processing’ and sustainable production that is fundamental to meeting the demands and expectations of Industry 4.0 and the markets we serve.”

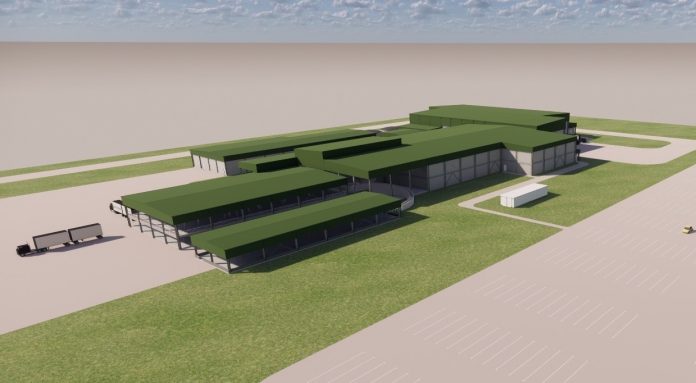

Subject to detailed design completion and final Development Approval, CirPro is focused on commencing construction as soon as possible with processing commencing by early 2023.