Article by JP van Loggerenberg, CTO at SYSPRO

The ongoing pandemic and supply chain disruptions have led many manufacturers and distributors to explore the benefits of a digitalisation strategy to remain resilient.

According to the recent SYSPRO research report entitled ‘Realigning the links of the disconnected supply chain’, in response to the immediate impact of the pandemic, 69 percent of manufacturers and distributors built a digitalisation strategy during the pandemic and 29 percent created a fully-fledged digital transformation with the aim of optimising their operational processes and improving their customer services.

As many as 71 percent of businesses that were surveyed engaged with outsourced external service providers with no fundamental understanding of core business challenges or everyday reality of what was affecting their business. Consequently, digitalisation strategies have not aligned with digital execution.

While almost half of manufacturing businesses included improving customer services in their digital strategy, only 18 percent of businesses invested in business systems to enhance external collaboration with those customers and even their supplier base.

Therefore, manufacturers need to develop and manage their digital roadmap, owning the process. Instead of relying on a service provider to execute that strategy, businesses should partner with a trusted advisor who can provide advice along the entire digital journey so that digital strategy meets digital execution. This approach is where the role of the project manager becomes vital.

How a project manager unlocks technological value for manufacturers

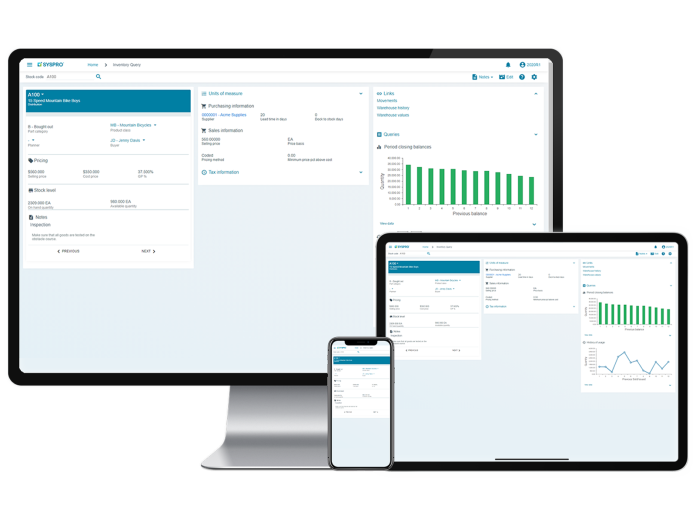

Once a digital strategy is agreed, a project manager is assigned to lead the implementation of a solution and oversee the whole project. The project manager ensures that the business’s strategic objectives are met while also ensuring that the full capabilities of a technological investment are unlocked. For many manufacturers this may include implementing a new ERP system that enables the visibility, control and a single source of data that they require.

The project manager’s role is multi-tiered. They will manage the implementation project, maintain communication at all levels inside and outside the project team, manage any scope issues, manage conflicts that may arise, make the decisions delegated to them and escalate those requiring resolution.

If a project is poorly managed, it could run the risk of running over target dates, exceeding budget and wasting valuable time. While project delivery is a collective effort, the project manager can ensure ERP project success by employing these essential strategies.

- Mitigating the risk of stakeholder buy-in

A major risk factor to be mitigated is stakeholder buy-in as people are generally resistant to change. This includes senior management support. The SYSPRO study showed that the true digital transformation champions within businesses were middle management (60 percent), while only 44 percent of C-level management supported digital transformation. Senior leadership support is imperative for businesses to digitally transform.

Upfront stakeholder buy-in is dependent on whether or not a digital strategy is accurately defined. A digital strategy should be addressing the critical pain points that a business may be experiencing and should be revisited often. During the pandemic, 60 percent of businesses were unable to have ongoing engagement with customers.

While external collaboration with the external eco-system has been identified as a key pain point, many have realised that ERP may be a solution to increase visibility across the supply chain. With that realisation and statistics to back-up the ERP investment, project managers can ensure stakeholder buy-in to avoid ongoing disruption along the supply chain.

- Incorporate a change management strategy

With the ongoing risk of stakeholder buy-in, the project manager should also work closely with the project management team to incorporate a rigorous change-management strategy. There are a number of change management models to consider, but one of the more popular or tried and tested models is the Prosci change management methodology. This model equips practitioners with a purpose-driven, performance-oriented process to achieve adoption and usage and realise successful outcomes from change.

- Measure, monitor and reassess

At the outset of the project, the project manager should set up a regular cadence of meetings with the project team to establish project milestones and with project stakeholders to ensure sponsorship. Questions that would need to be assessed on an ongoing basis include whether the ERP implementation is unlocking value such as time efficiencies and whether wastage is being minimised. Whether the supply chain is becoming more efficient and if there is a higher degree of visibility and co-operation between functional areas. The project manager also needs to focus on continuous incremental progress.

By working with an ERP vendor that places value on the customer relationship over the transaction by providing additional value through specialist consulting services and ongoing support and advice. It is essential to partner with trusted advisors to help companies along that journey so that they can minimise their mistakes and maximise thier value.

When implemented , ERP can offer a multitude of benefits and returns. The key to success is to be clear on the objectives, ensure stakeholders’ sponsorship and appoint a project manager who manages, implements and always places the project success together with customer experience at the centre of every decision.