Germany-based Fraunhofer IAPT has commissioned an independent study of the various additive manufacturing (AM) density determination technologies available and discovered that Dimensionics Density’s automated density determination is recommended in areas where a density statement must be made quickly or frequently.

Dimensionics, a division of Dimensionics GmbH, highlighted in a news release that the solution simplifies machine approvals and thereby lowers quality assurance costs.

In addition to Dimensionics Density technology, the Fraunhofer report titled, “Analysis of measurement methods for density determination in additive manufacturing” examined the use of micrographs, computed tomography, and the manual Archimedes method.

Although all approaches are capable of measuring the relative density of AM parts and components, the Fraunhofer IAPT research discovered significant variances in accuracy, resolution, repeatability, and defect identification.

According to the analysis, micrographs ruin the AM specimen, and while they can provide some insight into the real status of pores in a part, the process is labour-intensive, adding time and money and requiring a high level of expertise.

Dimensionics also stated the Archimedes method is the simplest to apply, but it also has the potential to be the least accurate because of its vulnerability to factors such as varying climatic conditions, the precision of the balance, and the exactness of the experimental procedure.

The results, which are heavily impacted by human variables, are challenging to replicate, and the company said that test specimens are never placed on the balance in precisely the same fashion, and measurement errors result from the manual operation of the balances.

Philipp Pruesse, head of sales at Dimensionics Density, said the firm is ecstatic that the Fraunhofer IAPT report highlighted the benefits of the automated density assessment procedure.

He detailed that the solution employs the Archimedes method but in conjunction with modern automation technology.

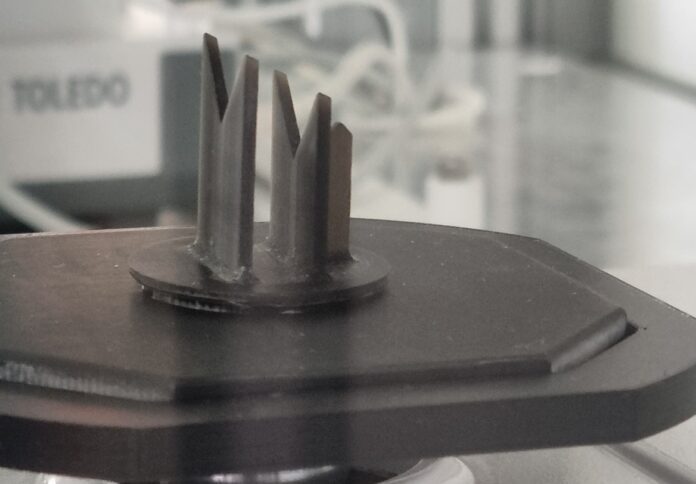

The samples to be measured are loaded into a customised component carrier having holes on the underside, and an axis robot transports these component carriers through the system, lowering them centrally and accurately into the scales.

Pruesse said a lift-out rack with pins is put on the scales, which lifts the component over the apertures in the component carrier and thereby lifts the component out of the carrier.

Because the parts are always positioned exactly on the scales, the automated handling eliminates human impact on the measurement, and the scales are meant to be vibration-free.

Furthermore, Pruesse explained that all environmental factors such as temperature, air pressure, and water temperature are recorded using climate sensors, and their impact on the measurement result is explicitly accounted for in the evaluation method for estimating the density.

According to the Fraunhofer IAPT benchmarking report, Dimensionics Density’s automatic density estimation eliminates the user from the Archimedean measurement, resulting in much higher repeatability and reduced variations.

It also claimed that this method is the only one that can be referenced to an accepted standard via a measurement chain since it is traceable.

“Dimensionic Density’s automated density determination solution is poised to revolutionize the analysis of component density, and we are delighted that the Fraunhofer IAPT report recognises its importance in the critical area of AM production part / process validation,” Pruesse noted.

He concluded that users will be able to advance their manufacturing processes to new heights and tap into the full potential of additive manufacturing.