Hazer Group Ltd (ASX: HZR) has announced a new partnership with US-based Particulate Solid Research, Inc (PSRI) to advance the commercial-scale rollout of its methane pyrolysis technology, strengthening its long-term strategy to deliver low-emission hydrogen at scale.

The collaboration will see Hazer leverage PSRI’s internationally recognised expertise in fluidisation and solids handling to optimise and de-risk the design of its commercial reactor systems.

PSRI, a research consortium known for supporting energy giants such as ExxonMobil, Shell and KBR, has played a role in the scale-up and commercialisation of more than 10 fluid bed process technologies.

“We are delighted to welcome Hazer Group as a member of PSRI,” said Reddy Karri, CEO of PSRI. “Hazer is a leader in methane pyrolysis technology and deploying a fluidised bed process is an excellent way to economically scale their innovative technology. We look forward to supporting Hazer’s commercialisation efforts and fostering a strong, knowledge-driven partnership.”

Hazer’s proprietary process converts methane into low-emission hydrogen and synthetic graphite using fluidised bed reactors, a system widely adopted in refining and metallurgical industries.

The company sees this as a key competitive advantage in meeting growing demand for hydrogen production, particularly for facilities requiring capacities above 50,000 tonnes per annum.

According to Hazer, the partnership with PSRI complements its existing alliance with KBR, which provides technology licensing and engineering support.

By combining KBR’s capabilities with PSRI’s deep fluidisation knowledge, the company aims to fast-track the development and validation of its reactor systems for commercial applications.

“Joining PSRI marks a significant step in our journey to commercialising the Hazer Process,” said Hazer CTO Tim Forbes. “PSRI’s unparalleled expertise in fluidisation will help optimise, de-risk and accelerate the deployment of our technology at scale while building deep organisational capability in fluid solids technology.”

Initial work between the two organisations will focus on large-scale cold flow testing to better understand the fluidisation behaviour of Hazer’s synthetic graphite by-product.

Findings will inform modelling, reactor optimisation and process design, with outcomes to be incorporated into the commercial process design package, which will be licensed through KBR.

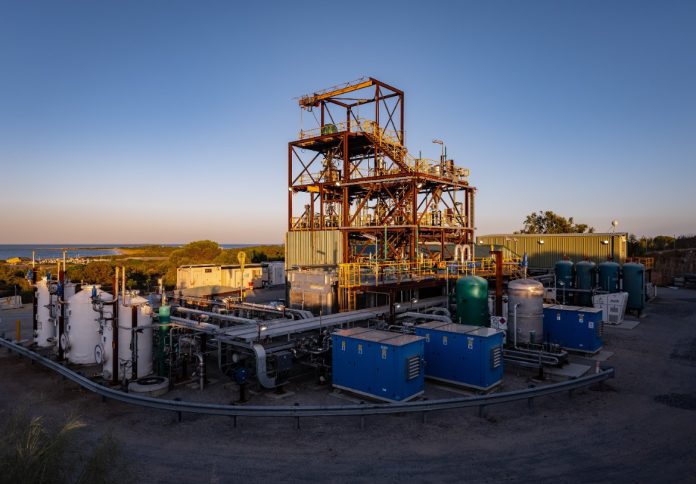

Hazer stated the new partnership builds on the commercial demonstration plant campaign conducted in 2024, which provided critical insights into its technology’s operational performance.