Northumbria University has been awarded over €250,000 under the European Union’s Marie Sklodowska-Curie Actions (MSCA) Fellowship to drive research into sustainable manufacturing processes for 3D-printed construction materials.

The project, led by Associate Professor Keerthan Poologanathan, Head of Structural Engineering at Northumbria, focuses on developing low-carbon, 3D-printable geopolymer mortars using alternative alkaline activators sourced from agricultural and industrial waste.

Dr Jyotirmoy Mishra, a postdoctoral researcher supported through the MSCA Fellowship, will join Northumbria to conduct the research alongside Associate Professor Dr Vikki Edmondson and Assistant Professor Dr Mohammadali Rezazadeh.

The initiative aims to reimagine the manufacturing of building materials by replacing carbon-intensive Portland cement with sustainable, waste-derived alternatives, the university said in a news release.

The research will explore the formulation and performance of geopolymer mortars in 3D printing applications – examining setting time, compressive strength, workability, durability, and environmental impact through a Life Cycle Assessment.

“I am truly honoured to receive the Marie Sk?odowska-Curie Postdoctoral Fellowship and to join Northumbria’s world-class Associate Professor Keerthan Poologanathan and his research team,” said Dr Mishra.

“This project allows me to contribute to cutting-edge innovation in sustainable construction by integrating material science, structural engineering, and digital manufacturing.”

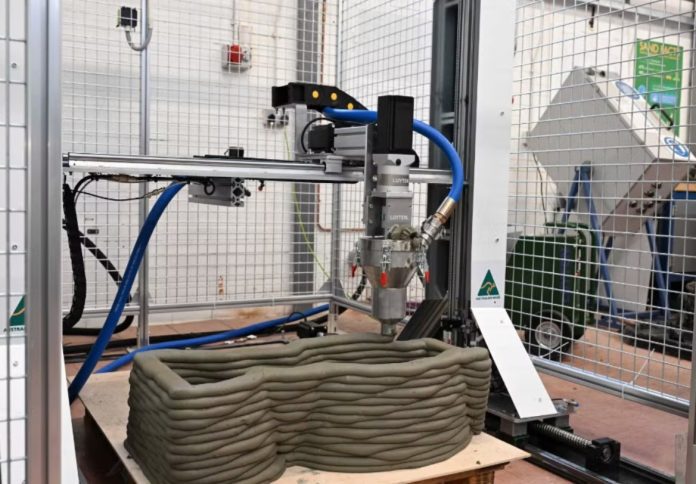

The use of 3D printing technologies in construction is gaining traction globally due to its potential to enable more efficient, cost-effective, and environmentally friendly building methods.

Northumbria’s focus on advanced manufacturing techniques within the construction sector reflects the growing demand for scalable, sustainable solutions in the built environment.

Speaking on the project, Dr Poologanathan said: “The MSCA Fellowship is a recognition of Northumbria’s research excellence and reinforces our position as a hub for advanced, interdisciplinary work in sustainable engineering. 3D-printed concrete is the future of sustainable construction—this research will help reduce carbon emissions, cut manufacturing costs, and minimise material waste.”

The research aligns with Northumbria’s broader commitment to addressing climate change and supporting the circular economy through innovative manufacturing practices.

Last year, the University expanded its Structures Laboratory with state-of-the-art 3D construction printing technology, through partnerships with global 3D printer manufacturer Luyten 3D and UK-based sustainable technology company ChangeMaker 3D.

Dr Mishra added, “The opportunity to explore waste-based alternative activators in 3D-printed geopolymer mortars is both timely and essential for addressing global climate challenges. Being awarded the MSCA Fellowship is a significant milestone that will enable me to translate research into industry-relevant, sustainable manufacturing solutions.”

For more information about research at Northumbria University, visit www.northumbria.ac.uk/research