Media Release by Orica

Orica (ASX: ORI) has today announced plans to install an Australian industry first tertiary catalyst abatement technology, EnviNOx® at its Kooragang Island manufacturing plant. The technology is designed to deliver up to 95 per cent abatement efficiencyi, reducing the site’s total greenhouse gas emissions by almost 50 per cent.

To accelerate Orica’s progress towards achieving its 2030 emissions reduction target, the $37 million Kooragang Island Decarbonisation Project will install proven nitrous oxide greenhouse gas (GHG) emissions tertiary abatement technology at its Kooragang Island plant from 2022, with commissioning in 2023.

To facilitate the project, the New South Wales Government’s Net Zero Industry and Innovation Program will co-invest $13.06 million, together with Orica’s $24 million financed by a 5-year debt facility provided by the Federal Government’s Clean Energy Finance Corporation. The Clean Energy Regulator has also approved the project as eligible to generate Australian Carbon Credit Units (ACCUs).

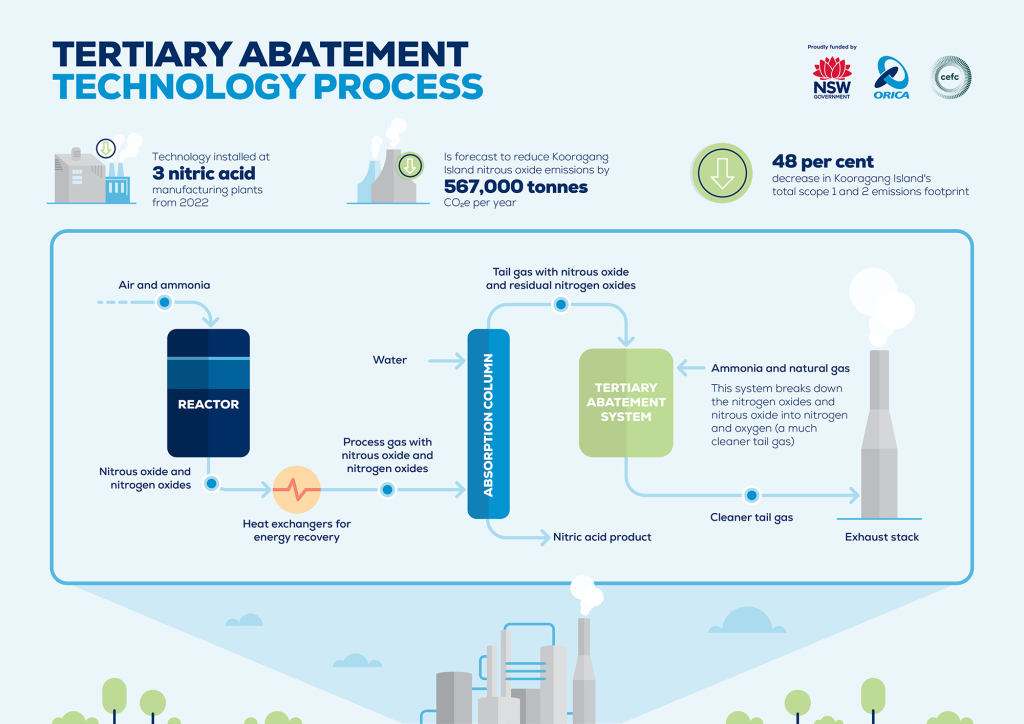

Viewed as a long-term aid for emissions reduction in high-pressure nitric acid manufacturing plants, the tertiary catalyst abatement technology utilises catalytic decomposition to destroy nitrous oxide emissions. Nitrous oxide, generated as a by-product of nitric acid production, is the primary source of GHG emissions at the Kooragang Island facility.

The technology will be installed across all three nitric acid manufacturing plants used in the production of ammonium nitrate at Kooragang Island, and is designed to eliminate at least 567,000 tCO2e per year from the site’s operations. It is expected to reduce the sites total emissions by 48% and deliver a cumulative emissions reduction of at least 4.7 MtCO2e by 2030 based on forecast production.ii

Orica Managing Director and Chief Executive Officer, Sanjeev Gandhi spoke about the critical role collaboration and partnerships will play in the decarbonisation of hard-to-abate industries, saying:

The Kooragang Island Decarbonisation Project is a powerful example of a public-private partnership towards decarbonisation and marks a critical step in achieving our medium-term 2030 emissions reduction targets and progress towards our net zero ambition. We’re committed to working with our stakeholders to forge a pathway towards a lower carbon future together.

“Thanks to the support of the New South Wales and Federal Governments we have been able to co-invest and move forward on implementing a significant decarbonisation project.”

New South Wales Treasurer, and Minister for Energy and Environment Matt Kean said: “The Kooragang Island Decarbonisation Project will contribute to the Government target of reducing NSW emissions by 50 per cent by 2030. The project is expected to deliver a cumulative emissions reduction equivalent to 567,000 tonnes of carbon dioxide per year providing significant decarbonisation benefits within the decade.

“This is a great example of what can be achieved by hard-to-abate industries transitioning towards net zero emissions, under our $750 million Net Zero Industry and Innovation Program announced earlier this year.”

In summarising the mutual benefits, Mr Gandhi said: “The project ensures our domestic manufacturing operations remain competitive in a low carbon economy, bringing with it significant environment and regional economic and social benefits.

“There are also benefits for our customers, by reducing the emissions intensity of our ammonium nitrate we are in a position to offer competitive and lower-carbon intensity ammonium nitrate products, helping them to achieve their sustainability goals.

“It also allows us to look at longer-term investments in technologies, including production of hydrogen from renewable energy.”

The Kooragang Island Decarbonisation Project was approved in March 2021 by the Clean Energy Regulator to participate in Australia’s carbon market. Orica is eligible to generate ACCUs and was awarded the first optional Carbon Abatement Contract under the Facility Method for the purchase of around 3.4 million ACCUs by the Australian Government. This approach has enabled investment confidence by managing ACCU price risk.

As Australia’s largest Mining Equipment, Technology and Services provider and a key player in the Australian manufacturing industry, a traditionally hard-to-abate sector, Orica understands that successful decarbonisation requires a collaborative approach. A founding member of the Australian Industry Energy Transition Initiative (Industry ETI), Orica is working with various stakeholders including government, industry, customers and civil society, to accelerate a pathway towards decarbonisation through proven, tangible action.

The technology is expected to be installed on the first nitric acid plant from 2022. The findings from the Kooragang Island Decarbonisation Project will serve as an important Australian industry case study, demonstrating the potential for tertiary catalyst abatement technology to be deployed more widely across the sector.

Orica has also recently partnered with the Alberta Government in Canada to commission a similar tertiary catalyst abatement technology at its Carseland?ammonium nitrate?manufacturing, reducing emissions by approximately 83,000 tCO2e per year. Orica has also assigned approximately $45 million over the next 5 years in capital to deploy similar tertiary abatement technology across its Australian ammonium nitrate sites, including its Kooragang Island site.

GHG emissions data and performance against targets will be reported annually as part of Orica’s annual reporting suite. Orica’s 2021 annual reporting suite will be published at the end of November 2021, including a Climate Action Report aligned to the recommendations of the Taskforce on Climate-related Financial Disclosures.

KEY FACTS

- The primary source of GHG emissions at the Kooragang Island facility is from the production of ammonia and nitric acid, both intermediaries in the production of ammonium nitrate. The production of nitric acid generates nitrous oxide as a by-product of catalytic oxidation of ammonia.

- In 2022, Orica will upgrade three nitric acid processing plants at its Kooragang Island site used in the production of ammonium nitrate, with technology designed to abate nitrous oxide emissions.

- This will be the first time the technology has been deployed in Australia, and is designed to deliver up to 95 per cent abatement efficiency from unabated levels. We expect to see a reduction in emissions by 567,000 tCO2e per year, and deliver a cumulative emissions reduction of at least 4.7 MtCO2e by 2030 based on forecast production.

- To facilitate the project, the New South Wales Government’s Net Zero Industry and Innovation Program will co-invest $13.06 million, together with Orica’s $24 million financed by a 5-year debt facility provided by the Federal Government’s Clean Energy Finance Corporation. The Clean Energy Regulator has also approved the project as eligible to generate Australian Carbon Credit Units.

- Kooragang Island employs 253 full time workers and contractors, and in 2019, $120 million was contributed to the New South Wales economy with over 1,500 additional jobs supported at state level. For every $1 million investment by Kooragang Island, an indicative $170,000 in additional activity occurs and 15 additional jobs are supported in the broader economy.

- Together with environmental outcomes, the project will ensure Orica’s domestic manufacturing operations remain competitive in a low carbon economy and continue to contribute to the local economy. Almost half of the $37 million project will be spent with local New South Wales suppliers. This builds on Orica’s history supporting local socio-economic development with two-thirds of suppliers to the site being located either in the Hunter Valley (38 per cent) or across New South Wales (28 per cent)

- Orica has recently announced a target to reduce scope 1 and 2 operational emissions by 40% (on FY19 levels), and an ambition to achieve net zero emissions by 2050iii.

TERTIARY ABATEMENT TECHNOLOGY

References