Article by David Alatorre, CTO, Rivelin Robotics

The various, often and well-discussed, advantages of Additive Manufacturing (AM) are real and this article in no way disputes them.

Indeed, Rivelin Robotics exists because the team believes in the broad potential of metal AM to contribute to a more sustainable business model for production as AM processes continue to transition from prototyping to competitive production processes. To achieve this goal, however, ideology and reality have to be reconciled.

In the real world, manufacturers that are utilising AM invariably face a number of challenges after their part(s) come off the AM machine. No longer a well-kept secret, the post processing of AM parts, particularly metal parts, remains dirty, labour-intensive, time-consuming and, as a result, expensive.

These significant pain points in the production process chain can often add a considerable burden that negates the benefits of utilising AM in the first place, especially on the economic front, when the cost-per-part can become fiscally prohibitive.

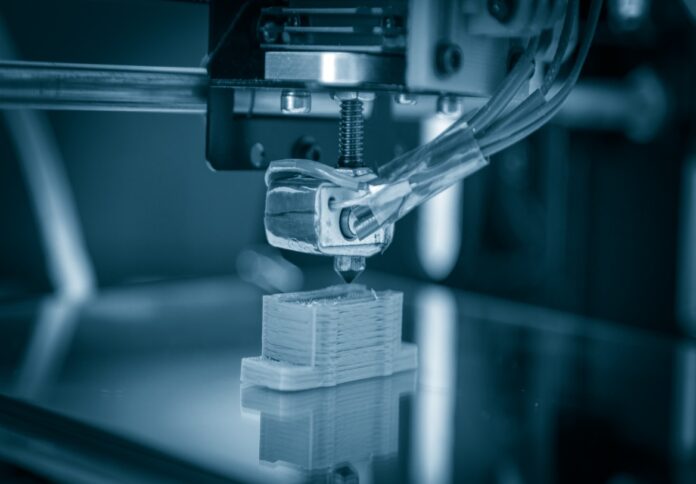

Post processing refers to the steps taken after the AM process has produced the parts on the industrial 3D printer. Each step is required to refine and improve the quality, mechanical properties and surface finish of the parts.

From the outset, it is important to identify the different metal AM processes commercially available. There are currently three dominant processes used for producing metal parts using AM. These are categorised as powder bed fusion (PBF) with either lasers or an electron beam (eBeam) utilised as the heat source; direct energy deposition (DED); and binder jetting. This article is focused primarily on the first category of PBF.

Overview

For OEMs that are assessing the use of AM for production, AM process selection is the primary consideration to determine the best process to build parts that fulfil the application relevant to the material, part geometry & function, part size and the volumes of parts required. However, serious consideration must also be given to any and all post-processing requirements. It is not overstating the situation to say that the use of AM as a viable alternative to traditional manufacturing processes may end up being negated completely in terms of time and cost if this is not done.

For any parts produced using a metal PBF AM system, the parts must go through a series of essential post build processes, including but not limited to removing and cleaning off the unfused powder, removing the build plate, removing all supports, surface finishing, validation and QA (dimensional accuracy, residual stresses / porosity etc).

Traditionally these post processes require a considerable amount of manual intervention and a highly trained, skilled workforce all of which come at significant additional cost. There are also a number of risks that need to be considered and, where possible, mitigated. This includes but is not limited to workforces being subjected to repetitive workflows, with risk of injury and tedium. This latter ‘risk’ of tedium may seem trivial, but when speaking to customers across industry, it is a real problem that many have to resolve to retain staff. Manual post processing procedures also make repeatability and consistent quality output much more difficult to attain and, importantly, document for validation and traceability purposes.

The Challenges of Powder Removal

The very nature of PBF involves processing powdered metal materials to produce net shape or near net shape parts. Thus, the first and most essential post processing step that must be undertaken once the parts are out of the PBF AM machine is to remove any excess powder – this includes removing it from intricate internal channels, undercuts, holes, and fine features. Un-melted powder used during the process can become trapped within such features, making it difficult to fully remove using traditional methods. Designing specific features into the part to allow appropriate accessibility for powder removal without damaging critical functional features of the part can go some way to mitigate this issue, but that is another article altogether, and does not fully eliminate the problem of powder removal, which still stands. It is hard to miss the irony that complex geometry is one of the key selling points of AM, while the complete removal of powder from such parts adds further complexity to this post processing step.

Today, powder removal from AM parts remains a critical pain point in the overall production process chain. Effective powder removal of un-melted metal powder is important because it impacts the surface finish, mechanical properties and overall quality of the final part. Powder extraction and retrieval can also contribute to recycling, reuse and sustainability goals.

Manual techniques generally require each part be air blasted by hand and for a part with a variety of complex features this can take multiple hours per part. Considering the nature of the powdered metal materials that are being processed, this also brings added challenges pertaining to staff health and safety. Fine metal particles, especially those containing toxic or hazardous elements, can become airborne and pose respiratory hazards to operators. Implementing proper ventilation, personal protective equipment (PPE), and dust control measures is crucial. Working with certain powdered metal types can also pose a risk of explosion if not handled correctly, which can require stringent atmospheric controls.

The Challenges of Platform and Support Removal

For metal AM part production, a build platform is often used to anchor the component to the machine during sintering. These slabs of metal serve as the first layer onto which metal is fused and have to be removed as a post-processing step. Platform removal is often carried out using wire EDM machines and bandsaws, but is sometimes done manually by cutting or breaking individual attachment points until the part or parts are free. Manual platform removal requires skill and finesse, as damage to the build plate or components has considerable cost implications.

The sacrificial material that connects the build platform to each component is referred to as support structures, and these are usually required to prevent distortion and ensure a successful outcome, particularly for complex geometries. Designing effective support structures that provide sufficient support during the printing process while also being relatively easy to remove is possible, but complicated and necessitates finding the right balance between support density, orientation, and attachment points. This requires expertise and, usually, iterative testing.

Regardless of any mitigation activities pre-build, post-build and post powder removal, the supports also have to be removed, requiring mechanical intervention that brings a whole new and familiar set of challenges. As with powder removal, this is especially challenging for intricate and complex geometries. Again, significant manual labour is required, which adds further time and cost implications as well as introducing the risk of damaging the part.

Extensive technical skills and expertise are required, but the work is repetitive and dull which can lead to complacency and in some cases, danger to self and others. As mentioned previously, conversations with key people across industry have highlighted this as a major problem in terms of schedules, lead times and staff retention.

The Challenges of Surface Finishing

Metal PBF parts often exhibit rough and uneven surfaces due to the layer-by-layer nature of the process. Post-processing is therefore often required to refine the surface finish for certain parts and component types. Once again, this adds a further step to the production process chain that can be both time-consuming and labour-intensive. Manual grinding and polishing methods as well automated techniques such as CNC machining can be used to finish parts.

While surface finish is often perceived to be an aesthetic issue, in reality it can also have functional implications as well. Metal parts produced using PBF can have inherent near-surface porosity and surface defects that can compromise mechanical integrity and reduce the part’s performance.

Finding Solutions Through Automation

In recent years there has been significant progress with new automation technologies, including robotics, AI and machine learning — indeed it has been a fast and furious decade of technology innovation on this front and the benefits are becoming irrefutable. These benefits are now manifesting for the AM industry in various forms, offering highly automated solutions for the post processing of metal PBF parts that enhance process chain efficiency dramatically and substantially reduce human intervention.

A growing number of companies across many industrial sectors are implementing automated robotic systems for powder removal, support removal and/or surface finishing to scale up their production runs with metal PBF. Scaling up is only one part of the equation, however, and an equal emphasis needs to be given to accuracy and repeatability. Manual intervention is not only slow, but it also makes it notoriously difficult to predict consistency. This is where automation, with machine learning alongside traditional deterministic control theory to optimise quality and repeatability, excels in delivering a truly autonomous solution to the post processing challenges that users of PBF AM have faced.

This level of automation has been shown to dramatically reduce defect rates while lowering operational costs significantly. If that is not enough to convince you, it also eliminates risk to workers and the variability problem.

Rivelin Netshape® robots can demonstrably reduce the burden of post-processing for near-net-shape metal manufacturing applications. With a range of solutions available the robots enable the automation of common metal AM post processing tasks — including support removal & surface finishing – which ensures greater productivity and efficiency while also protecting workers’ health, tackling skill shortages and reducing overall costs.