RMIT University researchers have developed new ultra-thin filters designed to separate valuable chemicals from liquid mixtures more efficiently, a breakthrough the university says could support cleaner and more sustainable manufacturing processes for medicines, dyes and other industrial products.

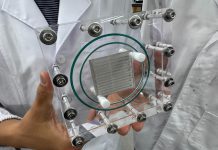

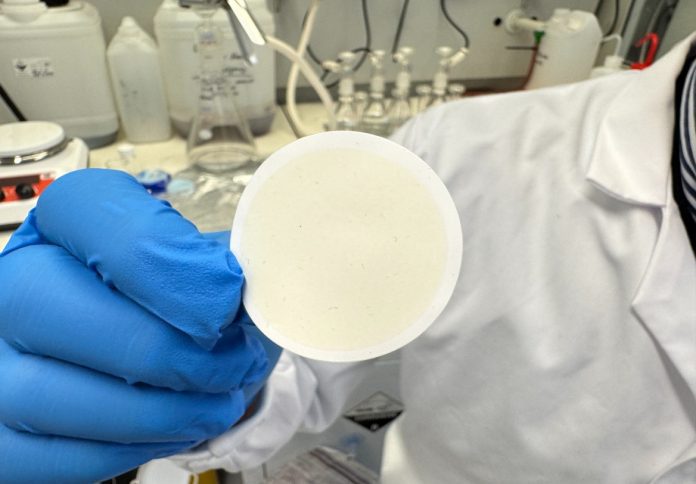

In a study led by PhD scholar Yuxi Ma and Professor Weiwei Lei from RMIT’s School of Science, the research team created hybrid filters that combine super-thin layers of boron nitride – a stable compound material – with tough synthetic fibres known as aramid.

According to RMIT, the result is a flexible but robust filter that remains stable even under high pressure.

“Boron nitride normally repels water, which makes it hard to combine with other materials,” Ma said in a statement from RMIT.

“We altered its surface so that it attracts water instead. That allowed us to form a stable, even mix with the fibres and create a much stronger composite filter.”

RMIT said the innovation could pave the way for more efficient and environmentally sustainable chemical manufacturing and recycling processes.

“Many industrial processes rely on solvents to produce or purify products, but separating out those solvents and re-using them can be slow and energy-intensive,” Ma said.

“Our filters let solvents pass through quickly while holding back larger molecules, offering a faster and more sustainable way to recover useful chemicals.”

The university reported that laboratory tests showed the filters performed effectively with common solvents such as ethanol, methanol and acetone.

The university also reported they maintained stability under pressures up to 10 bar – about ten times the pressure in a car tyre – and operated consistently for 24 hours of continuous use.

By adjusting the thickness of the filter’s active layer, the researchers said they could control how selective the filter was.

RMIT said a thickness of about one micrometre provided the best balance between flow rate and blocking performance, filtering out up to 96 per cent of larger dye molecules.

Ma noted that the simplicity of the design was among its key strengths. “Because the layers bond through natural hydrogen interactions, we can fine-tune the structure without needing complex chemical treatments,” he said.

“That makes the process easier to scale and more adaptable for different solvents or applications.”

According to RMIT, while the filters remained stable in mild conditions, performance was reduced in very alkaline environments, and certain harsh solvents caused gradual swelling.

The research team said it is now refining the chemistry to enhance durability and testing larger sheets under real-world conditions.

Professor Lei said the research brought advanced nanomaterials closer to industrial application.

“We’ve shown it’s possible to create an ultra-thin, pressure-resistant filter using materials that are lightweight and easy to handle,” Lei said. “Our next goal is to work with industry partners to scale up production and test the technology in chemical recycling and purification systems.”

Lei added that the technology could have wide-ranging industrial applications.

“Improving filtration efficiency isn’t just about saving time – it’s about cutting waste and enabling circular manufacturing,” he said. “With further development, we see strong potential for these filters to help industries transition to more sustainable processes.”

The research, titled “ANF/BN thin-film composite membranes for efficient organic solvent nanofiltration,” is published in the Journal of Membrane Science.