Researchers at RMIT University have developed a carbon-conversion technology that could turn industrial carbon dioxide emissions into ingredients for jet fuel and other carbon-based products.

In a news release, the university said the system integrates carbon removal and conversion into a single process, aiming to reduce the energy use and complexity that limit existing approaches.

“Current approaches had often been inefficient and energy-intensive,” said Distinguished Professor Tianyi Ma from RMIT’s School of Science.

“By bringing the steps of conversion together, we have been able to simplify the process and reduce unnecessary energy losses.”

Researchers said the technology converts carbon dioxide from industrial exhaust gases into chemical building blocks, which can later be processed into low-emissions jet fuel using established industrial methods.

While it does not directly produce jet fuel, the RMIT team said the system could provide a complementary pathway for aviation, which remains difficult to decarbonise due to limits on battery-powered aircraft and ongoing demand for sustainable aviation fuel.

“Our approach has reduced the number of processing steps and lowered energy demand compared with conventional systems,” said Dr Peng Li, lead author of the study.

“The RMIT system operates without the need for highly purified carbon dioxide, which is important in real industrial environments.”

The research, published in Nature Energy, outlines a fully integrated carbon-conversion process. Independent expert Dr Federico Dattila of the Polytechnic University of Turin said the work marked a step toward low-energy systems that can convert CO2 efficiently.

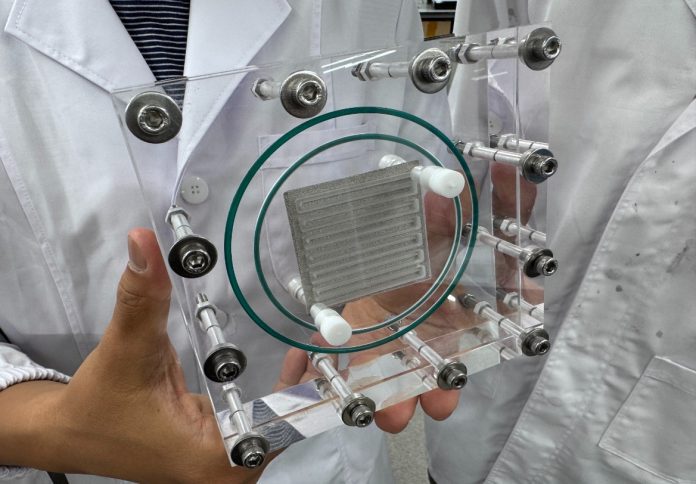

RMIT said the team has completed a three-kilowatt prototype to test the system under industrial conditions and plans a 20-kilowatt pilot to validate performance at larger scale. Industry partners involved in the development include Viva Energy, Hart Bioenergy, T-Power, Aqualux Energy, CO2CRC, ViPlus Dairy and CarbonNet.

“Scaling up has to happen hand in hand with industry,” Ma said. “That is the only way to understand what would work in practice and what still needs improvement.”

Doug Hartmann, chief executive of Hart Bioenergy, said the technology offered both environmental and operational benefits.

“This innovation has shown how emissions reduction could go alongside cost efficiency and better energy use,” he said.

The RMIT team plans a 100-kilowatt demonstration system within five years, aiming for commercial-scale readiness in around six years. Ma emphasised the approach is one part of a broader transition to cleaner fuels.

“This is not a silver bullet,” he said. “It is about developing practical tools that could help industries and governments reduce emissions while making use of existing systems during the transition to cleaner fuels.”

The study, titled Tandem amine scrubbing and CO2 electrolysis via direct piperazine carbamate reduction, is published in Nature Energy (DOI: 10.1038/s41560-025-01869-8).