ASX-listed company Sparc Technologies and Queensland University of Technology (QUT) have reached a significant milestone in their collaborative project that targets sustainably sourced hard carbon anode material for sodium-ion batteries (SIBs).

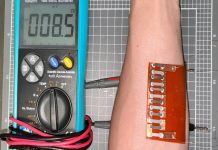

In a second project milestone report, QUT described the results of SIB half-cell battery testing and material characterisation from multiple samples of the chosen bio-waste material against a commercial benchmark.

According to the report, electrochemical testing confirmed consistently high reversible capacities and ongoing improvements in initial coulombic efficiencies for the bio-waste-derived anodes using the new processing method under development.

Sparc and QUT benchmarked the results against commercial hard carbon materials under the same testing procedure.

Enhancing the capacity of hard carbon anodes is considered a crucial factor for increasing the overall energy density of sodium-ion batteries, which is currently a key limitation to widespread use in mobility applications such as electric vehicles.

In a media release, Sparc said it is planning to accelerate its research and development efforts, with a focus on further optimisation of process parameters and testing to demonstrate a broader suite of battery characteristics.

“Sparc is extremely pleased with these results from its research with QUT into the development of sustainable hard carbon anode materials for sodium-ion batteries. The feedstock and process is demonstrating high capacity anode material which, subject to further testing and results, holds the potential to improve the energy density and carbon footprint of sodium-ion batteries,” said Stephen Hunt, executive chairman of Sparc Technologies.

“Sparc continues to see momentum building behind sodium-ion batteries as an alternative battery chemistry, driven by raw material availability and cost, and we remain well positioned as one of the only ASX-listed companies actively targeting this growing field.”

The results included in the latest milestone report were based on the preparation of hard carbon anodes using three different samples of the same category of bio-waste feedstock material. These samples, which differed by location, amount of upstream processing, and aging, were prepared and carbonised consistently using the method and conditions established in the initial process optimisation described in the March 2023 milestone report.