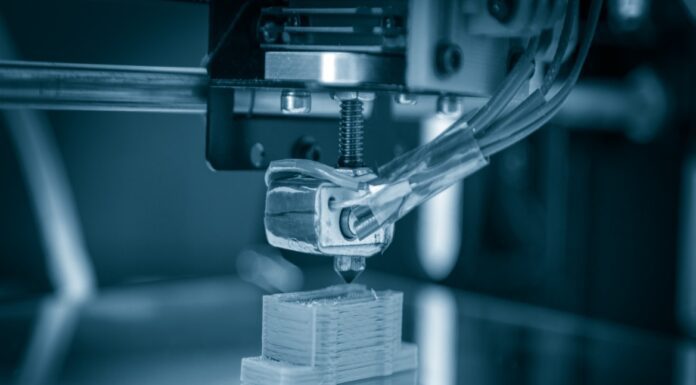

The US Army Corps of Engineers has granted a research team at Missouri S&T $1.4 million to create an artificial intelligence (AI) program that will choose the best locally accessible materials for 3D-printed concrete.

The project, led by Dr Kamal Khayat, will allow the Army Corps to 3D-print concrete structures more quickly without relying on vast volumes of construction materials being delivered, the university said in a news release.

“By harnessing the power of AI, our research team aims to streamline the process of material selection, ensuring optimal performance and cost-effectiveness,” said Khayat, S&T’s vice chancellor for research and innovation.

He added that the AI program will assess a wide range of locally available materials in diverse places to determine the best combinations for 3D printing concrete.

“This will enhance the efficiency of the construction process, improve troop safety, pave the way for more sustainable practices and help expedite humanitarian assistance missions,” Khayat noted.

According to the university, in order to substitute conventional cement materials, the team aims to use 50 per cent or more locally sourced or indigenous materials. The materials’ pumping, extruding, and construction-related use will all be tested.

Potential materials could include sources like rice husk ash, palm oil fuel ash, pulverised dolomite, and ground glass.

These materials could also come from natural minerals, industrial wastes, and agricultural waste, according to researchers.

According to Khayat, employing these materials might help enhance regional sustainability and boost the local economy.

Researchers noted that the 3D-printed structures will also be reinforced by a range of fibres.

Testing will be done on some metal and synthetic structural fibres as well as more unusual fibres made from plants and recyclable materials such bamboo, coconut, glass, hemp, cellulose, and rubber.

“This will be a comprehensive project that will make a significant difference in the mobility of our troops,” Khayat said.

He emphasised that costs associated with construction will also be significantly decreased, as will the number of material supply chain concerns.

Being a top university for investigating novel concrete materials for 3D printing, Missouri S&T said it is pleased to assist the federal government with this significant project.