Researchers at UBC Okanagan, in partnership with Drexel University, have unveiled a novel compound capable of revolutionising telecommunication antennas and connectivity devices through 3D printing.

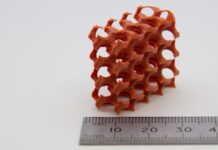

This innovative approach involves combining MXenes, a two-dimensional compound, with polymers to produce 3D-printed products that can serve as alternatives to conventional metallic counterparts.

The application of these MXene-polymer composites extends to various communication technology components, including antennas, waveguides, and filters, promising significant advancements in the field.

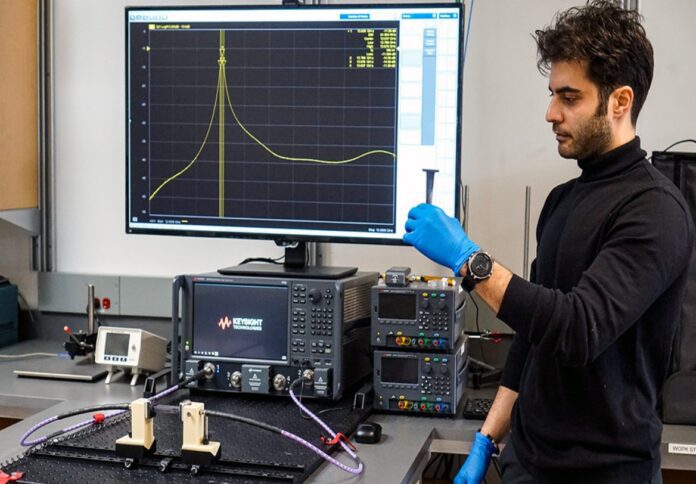

Dr Mohammad Zarifi, a key figure in UBC Okanagan’s Microelectronics and Gigahertz Applications (OMEGA) Lab, sheds light on the importance of waveguides in modern communication devices.

These structures, crucial for directing sound and optical waves, are traditionally crafted from metals due to their conductivity.

However, Dr Zarifi and his team have pioneered lightweight, cost-effective alternatives with performance levels comparable to metal, offering a transformative shift in waveguide technology.

“From the familiar hum of microwave ovens to the vast reach of satellite communication, these integral components have traditionally been made from metals like silver, brass and copper,” he noted.

According to Dr Yury Gogotsi, director of Drexel University’s A.J. Drexel Nanomaterials Institute, MXenes represent nanometer-thin conductive flakes that can be dispersed in water-like clay, providing a versatile and easily applicable material for enhancing polymer surfaces’ conductivity.

“This is a material that can be applied from dispersion in pure water with no additives to almost any surface. After drying in air, it can make polymer surfaces conductive. It’s like metallization at room temperature, without melting or evaporating a metal, without vacuum or temperature,” Dr Gogotsi stated.

The integration of MXenes into 3D-printed nylon-based components enhances their efficiency in guiding microwaves to specific frequency bands.

This breakthrough not only facilitates lightweight additive manufacturing but also holds immense potential for aerospace and satellite industries, as explained by Omid Niksan, a doctoral student at UBCO School of Engineering and the article’s first author.

The researchers have secured a provisional patent for their polymer-based MXene-coated communication components, signalling the immense prospects of this technology.

Dr Zarifi emphasised the sky-high potential of these advancements, particularly in space applications, where lightweight, efficient communication devices can significantly impact payload efficiency and engineering possibilities.

Supported by funding from the Department of National Defence, the Natural Sciences and Engineering Research Council, and the United States National Science Foundation, this collaborative research effort marks a significant milestone in materials science and communication technology.

Published in the journal Materials Today, the study sets the stage for further exploration and development of 3D-printed antennas and communication devices with unprecedented capabilities.