The University of Wollongong’s Innovation Campus is now home to the Australian Research Council’s new Training Centre for Innovative Composites for the Future of Sustainable Mining Equipment.

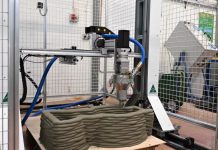

Over the next five years, the facility will develop novel materials for mining equipment that can be used in extreme underground conditions while making mining more eco-friendly and enhancing worker conditions.

Funded through a $5 million grant from the ARC, the new facility aims to train and produce highly qualified engineering graduates who will bring innovative solutions to the challenges facing the sector.

The training centre is backed by industry partners, including Roobuck Bisalloy Steels, SNS Unicorp, HBIS Group, Baosteel, Komatsu Australia, Top Iron, and Australia L&Y Mining Manufacturing.

Professor Zhengyi Jiang, the director of the new ARC centre, said the facility will bolster Australia’s position as a world-leading innovator in the Mining Equipment, Technology, and Service (METS) industry.

“This Centre, through collaboration with industry, aims to enhance and optimise research and development procedures, establishing a robust nationwide infrastructure to cater to the requirements of the mining equipment manufacturing sector, fostering sustainability, and creating a safer mining environment,” Professor Jiang said.

“The Centre is dedicated to bolstering the Australian industry’s role as a global pioneer in the METS sector to train young professionals for manufacturing and mining industries.”

Aside from training the next generation of researchers in innovative approaches to manufacturing and mining, the new centre also aims to boost Australia’s reputation worldwide within the industry and make the local mining industry more competitive globally.

Australia’s METS industry is expected to inject over $50 billion into the national economy and generate approximately 80,000 new jobs by the year 2030.

In a media release, the University of Wollongong said the sector is headed towards enhancing efficiency, cost-effectiveness, innovation, sustainability, and digitalisation of operations, developing the need for safer machinery and equipment capable of functioning in deeper mines and challenging environments.