UNSW Sydney researchers are advancing work on cleaner iron and steelmaking technologies in a bid to address one of the manufacturing sector’s largest sources of carbon emissions.

According to UNSW Professor Yansong Shen, who leads the university’s SCOPE Lab for Green Metals, current iron and steel production methods account for around 7 to 9 per cent of global carbon dioxide emissions – a level that underscores the need for viable low-emission manufacturing alternatives.

“Steel underpins almost all the structures and machines that we use every day, and demand for these metals is expected to persist well into the future,” Prof Shen said.

“When you build a steelmaking plant, you are effectively locking in the level of greenhouse gas emissions for decades, which is why developing greener production technologies as quickly as possible is so important.”

Prof Shen and his team are working with major industry partners including Baowu, BlueScope, Rio Tinto, and BHP to develop low-cost, low-emission ironmaking processes.

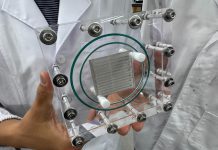

Among these are hydrogen-based direct reduced iron (H-DRI) and electric arc furnace (EAF) methods, as well as the lab’s Renewable Injectant and Sustainable Burden (RISB) technology, which modifies existing blast furnaces to reduce emissions.

“The RISB technology allows steelmakers to decarbonise existing sites without a complete rebuild,” Prof Shen said.

“While some residual emissions remain, this approach offers substantial reductions with high feasibility and lower cost.”

The research also explores other pathways such as waste-steel recycling and iron ore electrolysis, each with varying benefits and technical challenges.

Prof Shen noted that while green steel technologies promise emissions reductions of up to 90 per cent, cost and supply constraints remain key hurdles.

“The cost of green hydrogen and renewable electricity is still higher than conventional energy sources, making green steel 20 to 50 per cent more expensive than traditional steel,” he said.

Despite these challenges, Prof Shen believes greener iron and steel manufacturing could deliver both environmental and economic benefits.

“Producing iron and steel with lower emissions can significantly reduce pollution and improve community health,” he said. “At the same time, it opens up new opportunities for advanced manufacturing, exports, and skills development, particularly in regions rich in renewable resources.”

He added that developing practical, scalable technologies is critical to reducing the industry’s environmental footprint.

“If we want truly green metals, fixing the coal-based ironmaking step is the main challenge,” Prof Shen said. “That’s the key to a net-zero future for steel.”