Scientists at UNSW Sydney have used artificial intelligence to improve a method for producing green ammonia, achieving higher efficiency while reducing the need for extensive lab experiments.

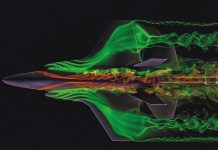

Ammonia, a key ingredient in fertilisers, is traditionally produced using the Haber–Bosch process, which operates at temperatures above 400°C and high pressure.

This energy-intensive method accounts for about 2% of global greenhouse gas emissions. In 2021, UNSW researchers reportedly developed a way to make ammonia using only air, water and renewable electricity at room temperature, offering a cleaner alternative.

Building on that work, the UNSW team led by Dr Ali Jalili used AI and machine learning to improve the process further by identifying the most effective catalyst.

Catalysts accelerate chemical reactions without being consumed, but finding the best one among thousands of possible metal combinations would normally require more than 8000 lab experiments.

“AI drastically reduced discovery time and resources, replacing thousands of trial-and-error experiments,” Dr Jalili said.

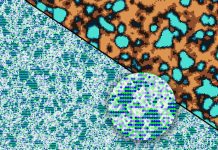

By training a machine learning system on the known behaviours of 13 different metals, the team reduced the number of necessary lab tests to just 28. The most effective catalyst turned out to be a combination of five metals: iron, bismuth, nickel, tin and zinc.

The result was a sevenfold increase in the ammonia production rate and a Faradaic efficiency close to 100%, meaning nearly all the electrical energy used in the reaction was converted into ammonia.

“This low-temperature, high-efficiency approach makes green ammonia production viable and scalable,” Dr Jalili said. “We believe it can compete directly with electrified Haber–Bosch and even fossil-based routes.”

The researchers are now trialling modular ammonia production systems, which combine the catalyst, plasma generator and electrolyser in a single unit about the size of a shipping container.

These units could allow farmers to produce ammonia fertiliser onsite, reducing costs and emissions from transport.

“Our approach breaks away from the era of centralised, giga-scale plants and opens the door for smaller, decentralised units that require much lower upfront investments,” Dr Jalili said.

The UNSW team also sees potential in using green ammonia as a hydrogen energy carrier. Because liquid ammonia stores more hydrogen than liquid hydrogen, it may play a role in energy storage and transport as part of a clean hydrogen economy.