Global engineering group GKN is expanding the deployment of Stratasys 3D printing across the manufacturing floor of its Florence plant to replace several traditional production processes and improve business performance.

GKN Driveline Florence services over 90% of the world’s car manufacturers with its automotive driveline systems and solutions.

Since the introduction of a Stratasys Fortus 450mc Production 3D Printer, the division has reported a 70% reduction in production time of certain tools, eliminating costly downtime of the production line and ensuring business continuity.

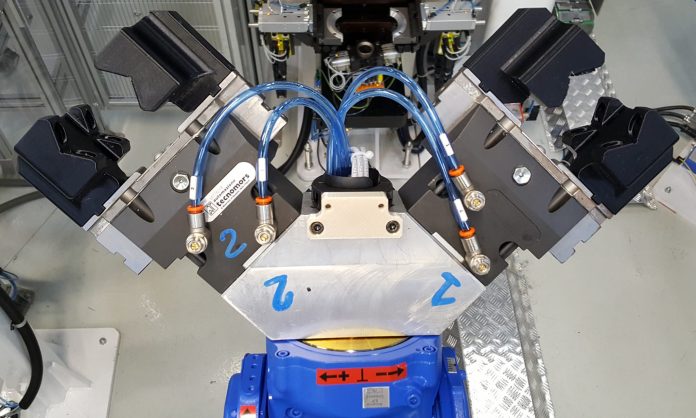

Carlo Cavallini, GKN Lead Process Engineer and Team Leader at the Florence plant, said his team can now produce complex assembly tools for the production line in a fraction of the time compared to traditional methods.

“Utilising our 3D printer, we developed a tool that dramatically improves grease distribution and eradicates the need to clean up time-consuming spillages,” Mr Cavallini remarked.

“This has been crucial to streamlining the production cycle of the half shaft, enabling us to provide customers with premium quality final parts.”

As customer lead times continue to shorten, the division has identified several new factory-floor applications where 3D printing can replace traditional manufacturing processes to produce customised replacement parts, on-demand.

“As we continue to design parts specifically for additive manufacturing, we are finding more and more applications that are delivering value,” Mr Cavallini continued.

“In the future, I believe that FDM 3D printing will become an integral part of our entire tool development cycle and help us further improve business performance.”

Andy Middleton, President, Stratasys EMEA, said GKN Driveline Florence was a prime example of how a growing number of future-ready companies are leveraging the capabilities of 3D printing to improve different areas of their business.

“We are committed to helping these customers identify traditional production processes that can be enhanced, or in some cases, replaced with our 3D printing solutions,” he stated.

“It’s this type of applied innovation across the manufacturing process that has seen GKN Driveline Florence accelerate product development, reduce costs and reinvent its supply chain.”