The University of Oklahoma (OU) and Oak Ridge National Laboratory (ORNL), the US Department of Energy’s largest science and energy laboratory, have announced a strategic collaboration to establish an advanced additive manufacturing centre in Norman, Oklahoma.

The initiative aims to accelerate innovation in metal additive manufacturing, with a particular focus on applications for aerospace and national defence, OU said in a news release.

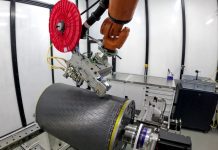

The new centre builds on OU’s Sooner Advanced Manufacturing Laboratory and ORNL’s Manufacturing Demonstration Facility, which is recognised as a national leader in advanced manufacturing research.

Through a joint effort led by OU’s Oklahoma Aerospace and Defence Innovation Institute (OADII) and ORNL, the collaboration will support research, workforce development, and training in areas including metal additive manufacturing, hybrid manufacturing, machining, and data analytics.

“This long-term partnership with Oak Ridge National Laboratory fully aligns with the recently published update of OU’s strategic plan,” said Gen Robin Rand (USAF, ret.), executive director of OADII.

“Our deliberate push to advance additive manufacturing research is fueling innovation and economic prosperity in Oklahoma and reducing risk to our nation’s defence.”

OU officials said the partnership would support key Department of Defence priorities such as sustainment and modernisation.

The Gallogly College of Engineering will play a major role in the centre’s operations, contributing to both academic advancement and regional economic development.

“Our college is thrilled to enter into this partnership,” said Zahed Siddique, associate dean for research at the Gallogly College of Engineering.

“Collaborating on cutting-edge manufacturing technology will enrich the student educational experience, expand research impact and enhance economic development opportunities in Oklahoma.”

The centre is expected to directly support operations at Tinker Air Force Base, as well as the Air Force Sustainment Centre and the Air Force Research Laboratory. Leaders from both institutions emphasised the potential national impact of the collaboration.

“This partnership between OU and ORNL will have a substantial impact on our national security, particularly by advancing qualified additive manufacturing processes for the sustainment and readiness of U.S. Air Force assets,” said Moe Khaleel, ORNL associate laboratory director for National Security Sciences.

“When the great people at our two institutions get together, with our collective resources, we will do big things for the nation.”

ORNL will contribute its technical expertise and operational experience from the Manufacturing Demonstration Facility to the collaboration.

Craig Blue, ORNL’s chief manufacturing officer and director of Defence Manufacturing Programs, said the partnership was designed to fast-track the deployment of innovative technologies.

“By combining ORNL’s deep expertise in advanced manufacturing with OU’s strong academic and research foundation, we are creating a dynamic ecosystem for innovation,” Blue said.

“This collaboration is not only about advancing technology—it’s about accelerating the transition of breakthrough solutions into real-world defence applications where speed, precision, and readiness matter most.”