Australia has marked a milestone in domestic space manufacturing with the successful production of the nation’s first bimetal rocket thruster using multi-material 3D printing, under a program led by the University of Southern Queensland (UniSQ).

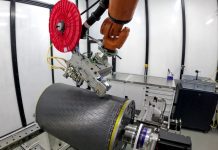

The thruster, developed by Space Machines Company (SMC), was manufactured at CSIRO’s Lab22 facility using a Nikon SLM Solution SLM280 2MA metal printer.

The innovation, funded through the UniSQ-led iLAuNCH Trailblazer program, will power Space Machines’ Optimus Viper, an Australian-built spacecraft designed for on-orbit inspection, servicing, and logistics.

The thruster merges high-strength steel for structural support and copper alloy for thermal conductivity in a single print, allowing it to endure extreme heat while remaining lightweight—a combination rarely achieved with traditional single-metal propulsion systems.

“We strive to build sovereign space capabilities by developing, manufacturing and operating space technology right here in Australia,” said Darin Lovett, Executive Director of iLAuNCH.

Conventional methods of manufacturing rocket thrust chambers involve machining cooling channels into copper liners and brazing them to steel jackets, a costly and time-intensive process with multiple potential failure points.

Multi-material 3D printing allows both metals to be produced simultaneously, reducing complexity, cost, and production time while increasing design flexibility and durability.

“By modifying our Scintilla thruster design to incorporate dual materials, we’ve gained the ability to rapidly experiment and optimise different material combinations – critical for achieving the propulsion performance our mass-produced spacecraft,” said Rajat Kulshrestha, CEO of Space Machines Company.

The thruster is a key component of Space Machines’ Scintilla propulsion system, delivering precise, repeatable thrust for close-proximity orbital operations.

Copper alloy channels provide regenerative cooling for repeated firings and long burn durations, while the steel jacket maintains structural integrity under pressure.

“This achievement showcases the potential of multi-material additive manufacturing for complex, high-performance parts,” said CSIRO Senior Research Scientist Dr Cherry Chen.

“Placing each material exactly where it’s needed improves functionality, reduces waste, and opens new design possibilities across industries such as automotive, biomedicine, and toolmaking.”

The iLAuNCH Trailblazer program, led by UniSQ in collaboration with the Australian National University and University of South Australia, involves over 25 industry and research partners.

Organisations interested in exploring multi-material metal 3D printing for advanced applications are encouraged to contact iLAuNCH or CSIRO’s Lab22 at ilaunch@unisq.edu.au.