The Commonwealth Scientific and Industrial Research Organisation (CSIRO) and research partners from the University of Padova (Italy) and the University of Adelaide have developed a viable new way of making sponge-like crystals that clean up contaminants in industrial waste and soil.

According to CSIRO, the new method reduces the production time for the new crystals from up to two days to as few as 15 minutes while also reducing the cost of manufacturing for as much as 30%.

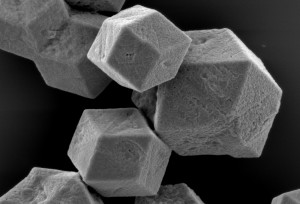

The crystals are composed of extremely porous metal organic frameworks (MOFs) and have an internal storage capacity of 7,000 square metres – equal to the size of a football oval in a single gram.

This allows them to filter huge volumes of industrial wastewater and trap great quantity of contaminants, including carcinogenic material and heavy metals.

CSIRO research team leader, Dr Paolo Falcaro, said the new production method slashed the length of time it took to produce MOFs, which had been the biggest obstacle to their manufacture until now.

“We’ve estimated that this process could cut the cost to make MOFs by thousands of dollars for Australian manufacturers,” Dr Falcaro said.

“While we’ve initially used the method to create zinc oxide-based MOFs, it could be applied to a range of different MOFs with applications spanning energy and pharmaceuticals.”

He said that unlike the traditional process for producing MOF crystals – which is extremely energy-intensive due to the heating and cooling required – the new method was performed at room temperature and delivered dramatic energy savings.

“We’re now seeking to work with Australian chemical manufacturers to further develop the method and explore turning the crystals into a sustainable industrial waste management product,” Dr Falcaro added.