Engineers at RMIT University have developed a new construction material made from cardboard, soil and water that has only a quarter of the carbon footprint of concrete while cutting down on waste going to landfill.

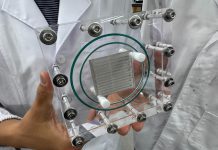

The material, called cardboard-confined rammed earth, is both reusable and recyclable, and offers a low-cost alternative for low-rise buildings.

According to RMIT, Australia alone sends more than 2.2 million tonnes of cardboard and paper to landfill each year, while cement and concrete production accounts for around 8 per cent of annual global emissions.

Lead author Dr Jiaming Ma from RMIT said the breakthrough could help reduce the construction industry’s reliance on cement.

“Modern rammed earth construction compacts soil with added cement for strength. Cement use is excessive given the natural thickness of rammed earth walls,” Ma said.

Unlike traditional methods, cardboard-confined rammed earth does not require cement. According to RMIT, the process produces walls that are robust enough to support structures, while costing less than one third of concrete.

“By simply using cardboard, soil and water, we can make walls robust enough to support low-rise buildings,” Ma said. “This innovation could revolutionise building design and construction, using locally sourced materials that are easier to recycle.”

Emeritus Professor Yi Min ‘Mike’ Xie, a structural optimisation expert and corresponding author of the study, said the material could significantly reduce transport and material costs.

“Instead of hauling in tonnes of bricks, steel and concrete, builders would only need to bring lightweight cardboard, as nearly all material can be obtained on site,” Xie said.

The team said the method is particularly suited for remote regions, including parts of regional Australia, where red soils are abundant and well-suited for rammed earth.

“Rammed earth buildings are ideal in hot climates because their high thermal mass naturally regulates indoor temperatures and humidity, reducing the need for mechanical cooling and cutting carbon emissions,” Ma said.

The strength of the material varies depending on the thickness of the cardboard tubes used, and RMIT researchers have developed a formula to calculate this relationship. “We’ve created a way to figure out how the thickness of the cardboard affects the strength of the rammed earth, allowing us to measure strength based on cardboard thickness,” Ma said.

In a related study, Ma and his colleagues also experimented with carbon fibre reinforcement, showing that rammed earth could achieve strength levels comparable to high-performance concrete.

The researchers said they are now seeking industry partners to help bring the technology into wider use.

Both studies are published in the journals Structures and Composite Structures.