RMIT researchers have collaborated with design firm Arup and Kristof Crolla of the Laboratory for Explorative Architecture and Design (LEAD) on a project designed to stretch the boundaries of the role of 3D printing in building and construction.

Image credit: www.rmit.edu.au

According to the press release by RMIT, the SmartNodes project was exploring the potential for using 3D printing to manufacture high-tech, lightweight SmartNodes that could be used with off-the-shelf, standard beams and fixings to construct a complex building.

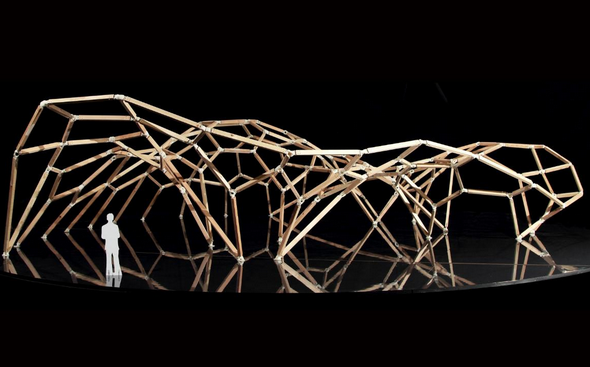

Associate Professor Jane Burry, from the School of Architecture and Design said the project had resulted in designs for more than 140 structural nodes used in the construction of a lightweight canopy.

“These SmartNodes will reduce building costs because they use less material, require less manufacturing processes and are quicker to manufacture. While 3D printing technologies have been around since the 1980s, it has had limited application in in the construction industry,” Mr Burry said.

“People in the construction industry have used 3D printing with concrete, but not with the materials we have used. The light weight of the SmartNodes means builders will save a lot on foundations, as well as on materials. There is interest from the construction industry, as well as technology, aerospace and medical because of the different forms we can create.”

Research fellow Nicholas Williams, who worked with Arup scientists on the project for a year, said the application of the SmartNodes system to architecture and engineering meant there was more flexibility in the building design without the extra cost.

“As a prototype, the team have designed a simple shell shape, which uses 144 different shaped nodes. They are light-weight and can contribute up to 15% of the structure’s mass, but by making them in these different shapes you can save weight and money, because you are using less material,” he said.

“There are a number of reasons this technology has not been used before, primarily the cost of production at the scale of buildings, combined with the uncertainty of material and process. SmartNodes tackles relatively small components, which are prototypes for larger scales of building form and structural stability.”

The project was led by researchers from RMIT’s Spatial Information Architecture Laboratory (SIAL) and included Professor Mike Xie in the Centre for Innovative Structures and Materials, and the Centre for Additive Manufacturing’s Professor Milan Brandt and Associate Professor Martin Leary.

“The designs and components will be tested by RMIT’s School of Civil, Environmental and Chemical Engineering, Design Research Institute and Arup. The pieces were used to build and exhibit the pavilion at last year’s Engineers Australia convention,” reads the press release.

“Testing will take place at RMIT’s Advanced Manufacturing Precinct, which brings together design and engineering.”