Researchers at RMIT University have developed a new experimental technique that uses contaminants in wastewater to enhance the production of green hydrogen, potentially reducing dependence on fresh water, a resource increasingly under pressure in many parts of the world.

The study, led by RMIT’s School of Science in collaboration with the University of Melbourne, Australian Synchrotron, and University of New South Wales, introduces a novel electrode design that turns wastewater’s typically problematic composition into an advantage.

The innovation could offer a sustainable and cost-effective pathway to produce green hydrogen while addressing water pollution, the university said in a news release.

“The advantage of our innovation over others to produce green hydrogen is that it harnesses wastewater’s inherent materials rather than requiring purified water or additional steps,” said Associate Professor Nasir Mahmood, the project’s lead researcher.

The team designed electrodes made from absorbent carbon surfaces capable of attracting and capturing metals such as platinum, chromium, and nickel from wastewater.

These metals then serve as catalysts, enhancing the water-splitting process used to produce hydrogen. The carbon material itself is derived from agricultural waste, further contributing to the innovation’s sustainability credentials.

“The catalyst speeds up a chemical reaction without being consumed in the process,” Mahmood explained. “The metals interact with other elements in the wastewater to boost the electrochemical reactions needed for splitting water into oxygen and hydrogen.”

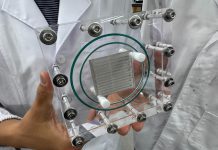

The process involves placing treated wastewater in a container with two electrodes – a cathode and an anode – and applying renewable electricity.

The result is the separation of water into hydrogen and oxygen gases. The team noted that oxygen generated through the process could also be reused in wastewater treatment plants to improve their efficiency.

The electrode system showed consistent performance in lab experiments, enabling continuous water splitting for 18 days with minimal efficiency loss. The wastewater used in the study had undergone partial treatment, including the removal of solids and nutrients.

Professor Nicky Eshtiaghi, co-lead researcher from RMIT’s School of Engineering, said the innovation could offer dual benefits by addressing pollution and generating renewable energy.

“Our innovation addresses both pollution reduction and water scarcity, benefiting the energy and water sectors,” Eshtiaghi said. “By using wastewater, the process helps reduce pollution and makes use of materials considered to be waste.”

RMIT is actively seeking industry and government partners to explore the commercial potential of this technology. “We are keen to work with companies globally that are addressing energy and waste as cost and sustainability challenges, as well as water authorities,” Eshtiaghi added.

Dr Muhammad Haris, another member of the research team, said more testing would be required to ensure the method’s broad applicability. “The method needs to be tested with different types of wastewater to ensure it works universally,” said Haris, also from RMIT’s School of Engineering.

The research, titled Harnessing wastewater as a catalyst modifier for sustainable hydrogen production, has been published in ACS Electrochemistry.