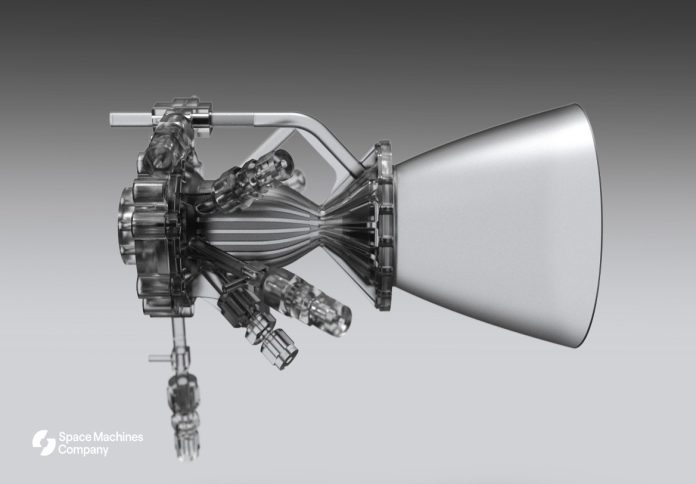

Space Machines Company has completed the development of its in-house Scintilla propulsion engine, a 3D-printed rocket engine designed to support rapid satellite deployment and manoeuvring.

In a news release, the company said the milestone strengthens its vertical integration strategy by keeping design, testing, and manufacturing in-house.

The Australian space technology company reported that the Scintilla engine achieved burn durations of up to 65 seconds, with more than 1,200 seconds of total testing time and 40 restarts to date.

Generating 50 Newtons of thrust with 92 per cent efficiency, the system surpassed initial targets and is designed for scalability, with a pathway to near 100 per cent efficiency.

“We’ve achieved faster progress than even our most optimistic schedules predicted,” said Rajat Kulshrestha, co-founder and CEO of Space Machines Company.

“The engine has reached steady-state conditions and demonstrated the ability to run for extended periods – a critical requirement for our satellite operations. We can now run this engine for minutes, limited only by total propellant supply from our tanks.”

Unlike many satellite manufacturers who outsource propulsion systems, Space Machines Company has focused on building its own technology. The company said this approach reflects the central role of propulsion in its Optimus Viper platform, which is being developed for rapid orbital manoeuvring and space domain awareness missions.

“Propulsion is absolutely core to what Space Machines needs to do,” said Ian Partis, vice president of engineering and mission operations at the company. “The better the propulsion system and the more delta-v available, the greater range of orbits we can access and the faster we can get there. This is so fundamental to our mission that the satellite is essentially a propulsion system with a payload on top.”

The Scintilla engine was manufactured entirely in-house using metal 3D-printing technology, which the company said allows for reliability, scalability, and rapid iteration.

The design incorporates restart capability for multiple ignition cycles and can scale thrust output from 50 Newtons to between 100 and 500 Newtons with relatively minor modifications.

Kulshrestha said vertical integration and in-house manufacturing provided significant advantages during development. “When the team identified an issue during testing, they were able to diagnose it within 10 minutes and implement solutions immediately. This kind of responsiveness is impossible when working with external suppliers,” he said.

Space Machines Company added that its “build-to-learn, learn-to-build” approach was instrumental in overcoming challenges during testing, enabling engineers to identify and correct potential failure modes while maintaining multiple backup systems.

“This achievement demonstrates that small, focused teams can deliver world-class propulsion systems on accelerated timelines,” Partis said.

“The propulsion-centric design of our Optimus Viper satellite represents a fundamentally different approach to space missions, where manoeuvrability and rapid response are paramount.”

With the propulsion engine development complete, the company said it is moving toward full subsystem integration, including flight-grade valves and propellant management systems, as it advances work on the Optimus Viper satellite.