The cutting-edge technology of commercial 3D printing or additive manufacturing can be a truly great asset to your small business, but alike all technology, it may not suit everyone…

Often the common misconceptions of 3D printing discourages small businesses and entrepreneurs from investing. As some believe the technology is too futuristic, expensive, and hard to use – but in reality, 3D printing is becoming more accessible, better quality and cheaper.

Since 2015, Emona Instruments has offered industry-leading 3D printers and materials to many manufactures Australia-wide. In this article, we share our top four reasons why small businesses should invest in 3D printing.

Optimised Manufacturing

The initial cost of a 3D printer will quickly pay for itself solely due to the profitable benefits gained from more effective assembly lines. This is because 3D printing does not require product moulds or tooling to produce a product, which reduces the time needed to create individual parts and production modifications, resulting in faster turnarounds.

Mass-producing goods with near-zero manual labour is now feasible thanks to 3D printing, making the overall scope-of-product far more economical, allowing products to hit the shelves quicker. With commercial 3D printing, there is no need to go through several middlemen and consultants to get a finished product.

Additionally, if anything goes wrong during production, removing or restoring defective pieces is a much easier process with a 3D Printer than with conventional machinery, saving costs and time overall.

Highly Customised Products

If your company’s primary focus is making custom objects, 3D printing is the most useful form of technology for you. With a build-on-demand business model, you can allow clients to customise their products at any batch size without significant additional costs or time.

Notably, Stereolithography (SLA) 3D Printers have become recently popular for the ability to produce highly accurate and high-resolution smooth surfaces. SLA uses a light source – a laser or projector – to form liquid resin into hardened plastic.

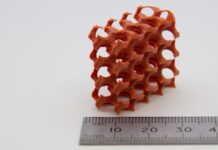

Through the precision of additive manufacturing, 3D manufacturers can conveniently access intricate geometries with amazing unique designs, previously not possible by human labour. Such complex jigsaw-like structures and special joints, not only looks good but also allow the product to achieve incredible strength and can make your object weigh less if desired.

Rapid Prototyping

Prototyping requires specialised small-batch manufacturing, which is usually an expensive and time-consuming process. But additive manufacturing considerably accelerates the prototyping process effectively, ensuring fast project development without wasting time or money.

Fused Deposition Modelling (FDM), or Fused Filament Fabrication (FFF) 3D Printers are the most cost-effective 3D Printers to produce functional products, best suited for prototyping and some non-commercial functional applications. In FDM printing, objects are built by melting materials through a heated nozzle, in a pre-determined digital method layer by layer.

Prototypes are particularly useful for trade shows and for in-store displays. Having a product preview helps potential customers get a physical sense of the brand, which will make you stand out from the competitors.

Storage and Resource Reduction

Especially for small businesses, storage is a common problem, as adequate physical storage is costly. Conventional manufacturing requires a large number of materials and a large amount of storage space. While with additive processing, some inventory can be digitally stored, allowing for far more flexibility in supply-chain management and overall lowering storage costs.

Need Commercial 3D Printers and 3D Printing Materials?

Particularly from a small business perspective, 3D printing will improve production – requiring fewer employees, equipment, and resources – and customer satisfaction with higher-quality products and hyper-customisation.

The potential of 3D printing is still in its infancy; in the coming years, almost all industries and companies will use the technology to enhance their manufacturing and supply chains. Be an early adopter of commercial 3D printing with a state-of-the-art 3D printer and high-quality 3D printing materials from Emona Instruments.

Emona Instruments caters for a range of budgets, functions and technologies, suitable for R&D professionals, production lines or the classroom. From Markforged Carbon Fibre Composite and Metal 3D Printer’s printing in stainless steel, tool steel, copper and Inconel, through to Formlabs SLA 3D Printers printing resin. Contact the Emona team for more expert information and technical support on (02) 9519 3933, email testinst@emona.com.au or visit www.emona.com.au/markforged.