Sponsored Content by

If you have used Fusion 360, you’re already aware that it’s a very powerful tool. A single cloud program for design, modelling, and manufacturing, Fusion 360 gives you instant access to CAD, CAM, sculpting for complex surfaces, sheet metal functionality, 2D drawing for assemblies, and animation and rendering capabilities. In addition to that there is also simulation, automation, ECAD for PCB boards, and additive manufacturing. That’s a lot to pack in to one environment and is often sufficient for most product designers and manufacturers.

What are Extensions and Why do they Exist?

But in an ever-changing world there are always new ways to work and new techniques to consider. Fusion 360 supplies fundamental capabilities that can meet the needs of a large base of customers, industries, and applications. Extensions provide a cost-effective way for customers to instantly access powerful additional capabilities, as and when they are needed. Customers have the freedom to activate (and deactivate) technology in line with the needs of the business, such as for fluctuations in seasonal production, for project-based collaborations or for budgetary cycles. This flexibility also allows businesses to experiment with innovative new technology with a minimal investment and risk.

All this means that you can still do everything you need to within Fusion 360, without the hassle of transferring your data and models between multiple software applications, removing the potential for disconnected tools and eliminating costly deployment overhead.

How Do Extensions Work?

Fusion 360 extensions give you access to advanced design and manufacturing capabilities, exactly when you need them. There’s nothing to install, no additional IT support needed, and no concerns about whether your new software will function properly with your existing CAD and CAM software. With all extensions already integrated into the Fusion 360 environment, you simply unlock the tools with a single click to start using additional functionality.

Fusion 360 extensions also come with a range of flexible subscription options. Want to try out functionality before you buy? There’s a 7-day free trial option for most extensions. Would a little extra capability help you accomplish your goals for a short-term project? Consider a monthly subscription or flex access to pay as you go – possibly just for a single day. To access extensions all you need is an existing Fusion 360 subscription; how long you commit to using the extension is entirely up to you.

Plus, when you’re looking to get more capability into your business, it’s a lot easier to start with what you already have – using software programs that your team is already familiar with is much faster than retraining your workforce from scratch. Autodesk also provides different training options to ensure your workforce is comfortable using these advanced tools, including free Zoom onboarding sessions focused on extensions with experienced product specialists who know how to get you up and running quickly. All this functionality gives your team more time and freedom to innovate, so you can focus on bringing your products to market quicker and more efficiently.

What Extensions are Available?

Autodesk offers a range of extensions to serve different needs within your design and manufacture business. Autodesk is constantly enhancing the functionality within Fusion 360 as well as adding to the range of available extensions. Currently, the following extensions are available –

- Machining Extension

- Generative Design Extension

- Additive Build Extension

- Nesting and Fabrication Extension

- Manage Extension

Enhance Your CAM Capabilities with the Machining Extension

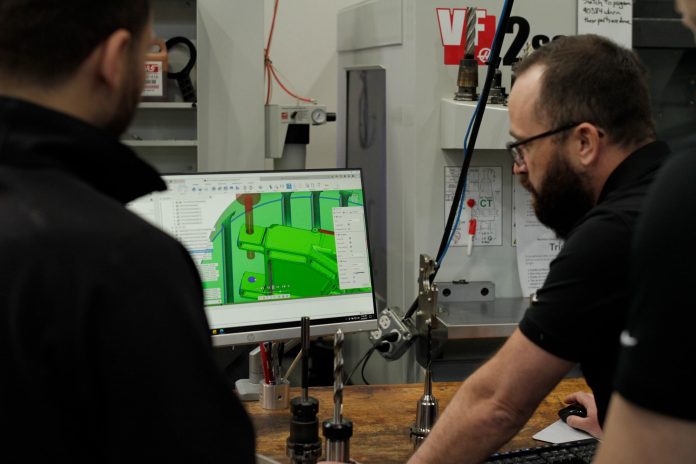

The Machining Extension boosts the core CAM capabilities of Fusion 360 with access to advanced 4- and 5-axis strategies, toolpath modification, and in-cycle probing cycles for process control and automated part setup. The extension includes advanced capabilities that were originally only available in more expensive products such as PowerMill (multi-axis strategies, toolpath modifications), FeatureCAM (5-axis hole recognition), and PowerInspect (in-cycle surface inspection and automated setup using spindle mounted probes). Crucially, the Machining Extension allows Fusion 360 users to access these highly valuable capabilities at a much lower, and more affordable price. This extension helps you produce better quality parts by simplifying and automating your CAM programming, allowing you to make better use of your CNC machines.

Based in the USA, Conturo Prototyping is one company who have made the extension part of their success. The Machining Extension has been well received and is considered as being extremely powerful, according to shop supervisor Patrick Fee.

“The Fusion 360 Machining Extension can do some really advanced stuff on the CNCs,” Fee says. “For example, part alignment typically involves a lot of shimming to make the part really flat. It can take hours, and it’s really stressful. With Fusion 360, the probe does all the work. That’s immensely time-saving and valuable to us. For us, the Extension paid for itself in the first job and in a matter of a few weeks.”

Find out more about how Conturo Prototyping are using the Machining Extension within Fusion 360 here.

Get More from Your Materials with the Nesting & Fabrication Extension

As the name suggests, the Nesting & Fabrication Extension in Fusion 360 unlocks advanced capabilities to create optimized and associative multi-sheet layouts for sheet metal and non-sheet metal parts. This extension lets the user access automatic nesting with grouping based on material, thickness, and grain orientation to improve the utilization of sheet materials, minimize waste, and increase profitability.

One customer who is already using the Nesting and Fabrication Extension is Ganas Manufacturing. They found one of the biggest benefits is maximizing the yield of sheet goods when accommodating several smaller pieces is automatically determined.

“There is a big gap in the woodworking and millwork industry when it comes to nesting,” Ganas says. “There are a lot of products for cabinet libraries, but they are not custom. Fusion 360 can do nesting directly from the 3D model and that’s invaluable to us.”

The impact of the Nesting & Fabrication Extension in Fusion 360 is huge for the shop, reducing expected scrap from 25% to just 5% of any given sheet. You can read the full Ganas Manufacturing case study here.

Take Control of your Data with the Manage Extension

Get additional data management functionality and manage design changes at any stage of production with the click of a button using pre-built workflows. Unlock capabilities for engineering change orders, release management, automated part numbering, and email notifications. The Manage Extension within Fusion 360 gives you complete visibility and digitally approved records so that you can focus on innovation, not administration.

“As a team, we are able to collaboratively use the cloud to review the current design and discuss even when not physically in the same location” states Annika Klüpfel of Breeze Automation, a company using Fusion 360 to create a new generation of dexterous robots and automation.

Harness the Power of Machine Learning and AI with the Generative Design Extension

For many, the idea of AI and machine learning sounds like something from a sci-fi film. In fact, AI is already having a positive impact on designers and manufacturers of the products we’re all using today. The Generative Design Extension allows you to rapidly explore new designs that solve some of the biggest challenges we’re facing today – reduce weight, increase structural integrity, improve performance, extend durability and increase productivity. This extension allows you to explore unlimited manufacturing-ready design outcomes that meet your specifications and allow you to explore designs that, quite simply, are beyond the reach of human capacity.

“Generative design algorithms in Fusion 360 iterate thousands of times a minute to the point where after only four hours you can have the most optimized solution possible – saving an unbelievable amount of time in the process” comments Ian Briggs of Briggs Automotive Company (BAC), a high-performance car manufacturer using Autodesk products to embrace digital transformation. Find out more about BAC and their use of Generative Design to build Mono sports car here.

Build Higher Value Additive Parts with the Additive Build Extension

Unlock extra additive manufacturing technology inside Fusion 360 with the Additive Build Extension. Product Metal parts with powder bed fusion (SLM) machines. Gain access to advanced features like automatic orientation and packing to maximise the use of build space. Use powerful simulation capabilities to validate upfront engineering and produce optimized geometry to minimize things like warp.

“Within 10 minutes we see something in 3D and then send it to the 3D printer” commented Ian Redfern, Senior Industrial Designer at Fabric. Watch how Fabric use Fusion 360 and the additive capabilities within the Additive Build Extension to create their award-winning bicycles here.

Learn More

As your business develops and evolves, Autodesk Fusion 360 will grow and adapt with you. Autodesk is here to help you take your business in the direction you need it go and discover the new possible.

To find out more about Fusion 360 extensions visit our extensions overview page or reach out to our team.