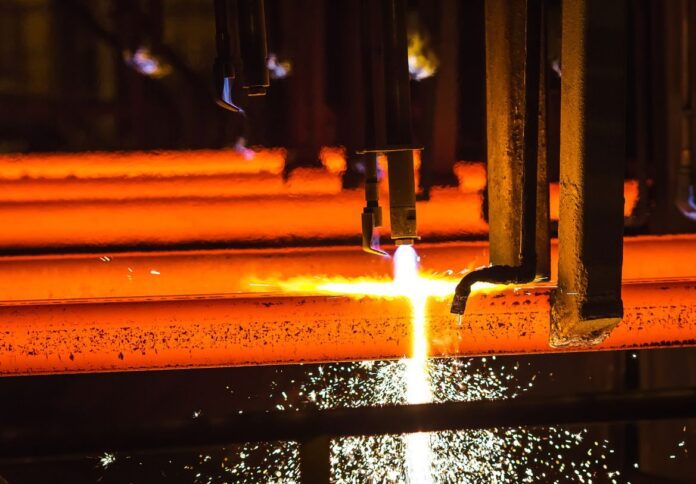

Weld Australia, in collaboration with the industry, government, and statutory bodies, are proposing initiatives to ensure that appropriate strategies are in place to reduce welder exposure to fumes and prevent long-term health effects.

According to Weld Australia CEO Geoff Crittenden, “Welding can and should be considered a safe occupation; when proper precautions are taken, welders have no cause to fear accident or injury. But when safety isn’t taken seriously in the workplace, the risk of a severe incident becomes a real concern.”

In a media release, Weld Australia said it has published a wide range of welding safety resources, including “Fume Minimisation Guidelines: Welding, Cutting, Brazing and Soldering,” which includes all the necessary information to help protect workers from the hazards associated with welding fumes.

Completely free of charge, the non-profit organisation also released “Technical Note 7: Health and Safety in Welding,” which gives guidance on health and safety practices in welding, cutting and other allied processes.

These processes include brazing, soldering, pre- and post-weld material treatments and metal spraying intended for the prevention of injury, ill health and discomfort, as well as damage to property, equipment and environment by fire, and explosion.

Crittenden underscored that adequate measures must be taken to lessen welder exposure to fumes and avoid the potential long-term health impacts of exposure.

He said that all welders should be trained on how to minimise the impacts of metal fumes, including how to position themselves to limit exposure and, when possible, look into less harmful alternatives.

To achieve these goals, Weld Australia said it is currently developing two comprehensive online welder safety training courses.

Welding engineers and supervisors are the focus of one course, while welders are the target audience for the other.

The topics covered in these seminars span from electric arc welding and flame cutting to welding fume safety and welding in confined spaces, at heights, or in hot and humid environments.

By the end of the year, these courses will be finished and publicly accessible on the Weld Australia website, according to the organisation.

“Education is the key to ensuring a safe and productive working environment for everyone. Employers need to invest in thorough and up-to-date training for all their employees to ensure that they understand the risks associated with welding, the mitigation strategies they can use, and the equipment available to prevent accident and injury, ” Crittenden explained.

“As the Responsible International Institute of Welding (IIW) representative in Australia, Weld Australia is at the forefront of global welder safety best practice. We regularly participate in international research and development programs designed to improve welding fume safety practices,” added Crittenden.

According to Weld Australia, Local Exhaust Ventilation (LEV) systems catch and extract welding smoke at the source, and they are a proven method of decreasing exposure.

It added that all workplaces should have appropriate LEV systems installed and maintained on a regular basis.

Powered air-purifying respirators (PAPR) are another effective way to reduce welder exposure to welding fumes in accordance with WHS requirements, the organisation said.