An initiative intended to help stimulate small to medium sized businesses to adopt the latest wave of technology in additive manufacturing will be spearheaded by Griffith University, as part of the Innovative Manufacturing Cooperative Research Centre (IMCRC).

Image credit: Griffith University

Supported with a Commonwealth funding of $40 million and a matched funding by over $210 million of cash and in-kind contributions from industry, research institutions and State governments, IMCRC’s research will be concentrated on high-growth sectors to help companies build the innovative capacity to develop market-ready opportunities.

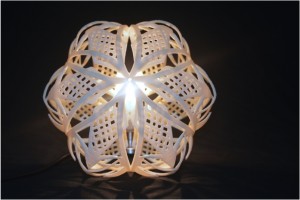

“Making the transition from conventional technology to innovative manufacturing is more than just investing in the technology, it is also about understanding the opportunities technologies such as 3D Printing are providing, and how to maximise it your business,” said Dr Jennifer Loy, Program Leader of Industrial Design at Griffith University.

“The investment of over $85 million in cash by government, industry and research will allow us to support a host of businesses from film to construction, lighting and furniture, mining through to medical devices, as they transition to 3D Printing technology over the next seven to eight years.”

According to Dr Loy, Griffith University has the expertise available to work side by side with the IMCRC to regenerate Australia’s manufacturing industries.

“It’s the perfect synergistic relationship as Griffith University has a collaborative working model and are particularly good at cross disciplinary projects – which innovative manufacturing creates – and we are keen to work with industrial partners on pushing the capabilities of innovative manufacturing for their new applications,” she said.

“Griffith is working hard to develop graduates who have the specialised skills needed to help industry and maximise opportunities for growth. Our Industrial Design and 3D Design Digital Media students are learning world leading software for additive manufacturing, and gaining hands-on experience of designing with advanced digital technologies, including 3D Printing, scanning and electronics for new design applications.”

The IMCRC is a collaboration of 14 initial manufacturing companies and end users who are already global, innovative and prepared to innovate further including many participants from the successful Advance Manufacturing CRC; 4 peak industry bodies that will help recruit over 300 additional SMEs as “Portal Partners”; and 16 Australian universities, CSIRO and the Fraunhofer Institute for Laser Technology.